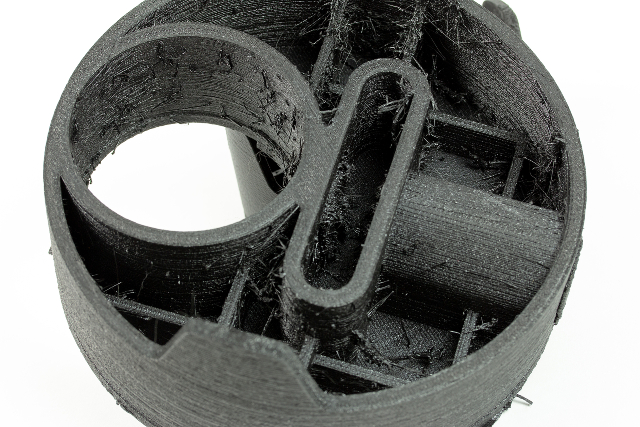

Parts printed from improperly stored materials exhibit poorer mechanical properties and lower optical quality.

The pre-programmed MMS preparation modes ensure durable and accurate prints without visual errors.

3DGENCE CONNECT

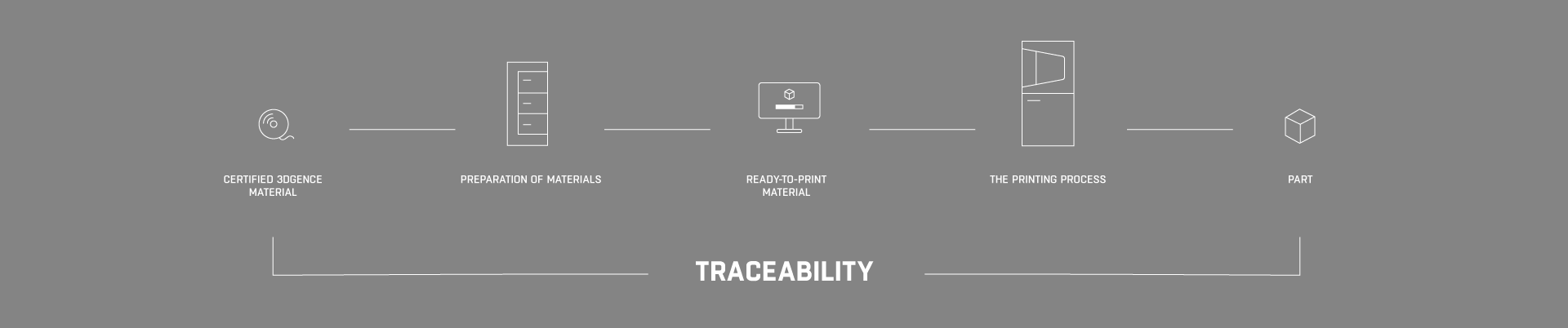

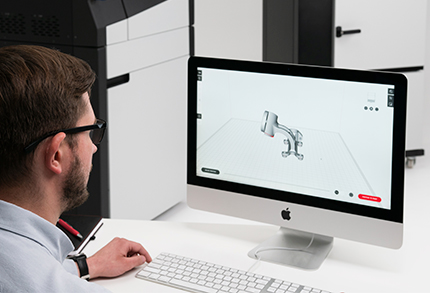

3DGence MMS benefits from 3DGENCE CONNECT, an ever-expanding and fully connected system between software, hardware and process control – with more connected features coming soon. Rely on control and traceability across the entire printing process – from design to part.

Scan the material into the MMS to register it in your printing process and get full material traceability. Proper material management is critical to part quality and integrity. We make it easy and keep it connected. Our application engineers are on hand to explain the technical details of the 3DGence Connected System.

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/3dgence-material-managment-system_MMS.jpg?v=1685393997&width=1214)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/mms-Krzysztof-podmiana.jpg?v=1685393997&width=1214)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/kolaz_3-scaled.jpg?v=1685393997&width=1214)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/2-1024x480.jpg?v=1685393997&width=1214)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/MMS-JPG-3.jpg?v=1685393997&width=1214)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/4_430_293.jpg?v=1685393997&width=1214)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/image_f8685f55-ff85-457e-83b0-38059db5b351.png?v=1685393997&width=1214)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/3dgence-material-managment-system_MMS.jpg?v=1685393997&width=88)

![Polymaker PolyTerra PLA Dual 1,75mm 1kg - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/PolyTerra-Dual-PLA_1-75mm_1kg_Foggy-Purple-Purple_600x600_d536672b-71f5-4400-a9af-a045bd9a226d.jpg?v=1700312155&width=176)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/3dgence-material-managment-system_MMS.jpg?v=1685393997&width=640)