Raise3D

Raise3D PRO3 Series Interchangeable Hot End Assembly with V3H Nozzle

€141,90Unit price /UnavailableIn stock (18 units)Raise3D

Raise3D PRO3 series Interchangeable Hot End with 0.4mm Brass Nozzle

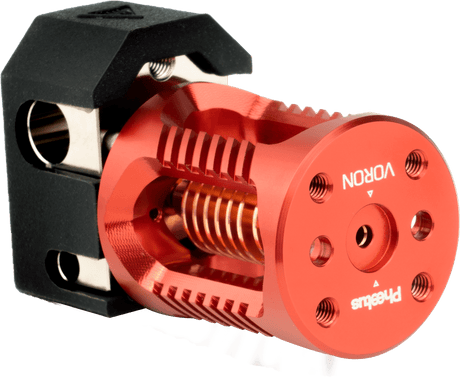

€130,50Unit price /UnavailableIn stock (19 units)Micro Swiss

Micro Swiss direct drive extruder with hotend for Creality CR-10 / Ender-3

€117,00Unit price /UnavailableRaise3D

Raise3D PRO3 series extruder left (without hot end)

€261,00Unit price /UnavailableVery low stock (1 unit)Micro Swiss

Micro Swiss direct drive extruder with hotend for Creality Ender 5 series

€117,00Unit price /UnavailableLow stock (7 units)Raise3D

Raise3D Pro2 Series Dual Extruders

€324,54Unit price /UnavailableVery low stock (2 units)3D Solex

3DSolex Printcore AA for Ultimaker S5/S3/UM3 Hardcore Tri-X 0.80mm

€175,90Unit price /Unavailable3D Solex

3DSolex Printcore BB PVA for Ultimaker S5/S3/UM3 with 2 nozzles

€156,90Unit price /UnavailableLow stock (4 units)Raise3D

Raise3D PRO3 series extruder right (without hot end)

€261,00Unit price /UnavailableVery low stock (2 units)Raise3D

Raise3D E2CF Left Print Head with Auto-leveling System Assembly

€460,91Unit price /UnavailableVery low stock (1 unit)

![Extruder und Hotends - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/collections/5-02-05035A01-Dual-Extruder-1_61aff434-e20a-4d0f-852d-0fa58e6351d1.png?v=1758821643&width=1296)

![Raise3D PRO3 Serie austauschbares Hot End Assembly mit V3H Nozzle - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-Pro3-Interchangeable-Hot-End-Pro3-Series-Only.jpg?v=1671225832&width=460)

![Raise3D PRO3 Serie austauschbares Hot End Assembly mit V3H Nozzle - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-Pro3-Interchangeable-Hot-End-Pro3-Series-Only-2.jpg?v=1671225833&width=460)

![Bondtech Hotend Fix für Raise3D Pro2 - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/files/Raise3D-Pro2-hotend-fix-7379-2500px-scaled.jpg?v=1684264061&width=460)

![Bondtech Hotend Fix für Raise3D Pro2 - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/files/Raise3D-Pro2-hotend-fix-7382-2500px-scaled.jpg?v=1684264061&width=460)

![Raise3D PRO3 Serie Extruder links (ohne Hot End) - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-Pro3-Series-Left-Extruder-Without-Hot-End.jpg?v=1671316096&width=460)

![Raise3D PRO3 Serie Extruder links (ohne Hot End) - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-Pro3-Series-Left-Extruder-Without-Hot-End-2.jpg?v=1671316096&width=460)

![Micro Swiss Direct Drive Extruder mit Hotend - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Micro-Swiss-Direct-Drive-Extruder-for-Creality-Ender-5-with-hotend-2.png?v=1660778820&width=460)

![3DSolex Printcore AA für Ultimaker S5/S3/UM3 Hardcore Tri-X 0.80mm - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/files/FA0994DE-5512-4E78-89A2-6A1D8FE33348-416x416.png?v=1700318933&width=460)

![3DSolex Printcore AA für Ultimaker S5/S3/UM3 Hardcore Tri-X 0.80mm - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/files/E8512B8B-E6A4-4A5E-9709-4216E5D8B709-600x561_06182db1-c32b-42b1-be67-4f0d231119f1.jpg?v=1700318933&width=460)

![3DSolex Printcore BB PVA für Ultimaker S5/S3/UM3 mit 2 Düsen - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/files/x3D-Solex-HARDCORE-PVA-BB-fur-Ultimaker-3_600x600-pagespeed-ic-JtLviVJl5v.png?v=1700319095&width=460)

![3DSolex Printcore BB PVA für Ultimaker S5/S3/UM3 mit 2 Düsen - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/files/E8512B8B-E6A4-4A5E-9709-4216E5D8B709-600x561.jpg?v=1700319095&width=460)

![ANKERMAKE M5 HOTEND SET - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/files/AnkerMake-M5-HotEnd-V7130041-28503.jpg?v=1684355405&width=460)

![ANKERMAKE M5 HOTEND SET - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/files/AnkerMake-M5-HotEnd-V7130041-28503_1.jpg?v=1684355405&width=460)

![Raise3D PRO3 Serie Extruder rechts (ohne Hot End) - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-Pro3-Series-Right-Extruder-Without-Hot-End.jpg?v=1671314686&width=460)

![Raise3D PRO3 Serie Extruder rechts (ohne Hot End) - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-Pro3-Series-Right-Extruder-Without-Hot-End-2.jpg?v=1671314687&width=460)

![Raise3D E2CF Left Print Head mit Auto-leveling System Assembly - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/E2CF-Left-Print-Head-With-Auto-leveling-System-Assembly-1.jpg?v=1671227463&width=460)

![Raise3D E2CF Left Print Head mit Auto-leveling System Assembly - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/E2CF-Left-Print-Head-With-Auto-leveling-System-Assembly-3.jpg?v=1671227463&width=460)

![Polymaker Polyterra PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/PolyTerra-Charcoal-Black-1.png?v=1700308626&width=460)

![Polymaker Polyterra PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/PolyTerra-Sapphire-Blue-700x700.png?v=1700308626&width=460)

![Polymaker Polyterra PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/PolyTerra-Savannah-Yellow-700x700.png?v=1700308595&width=460)

![Polymaker Polyterra PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/PolyTerra-Lava-Red-3.png?v=1700308595&width=460)

![Polymaker Polyterra PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/PolyTerra-Fossil-Grey3.png?v=1700308595&width=460)

![Polymaker Polyterra PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/PolyTerra-Forrest-Green-700x700.png?v=1700308595&width=460)

![Polymaker Polyterra PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/PolyTerra-Lavender-700x700.png?v=1700308595&width=460)

![Polymaker Polyterra PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/PolyTerra-Mint-700x700.png?v=1700308595&width=460)

![Polymaker Polyterra PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/PolyTerra-Sunrise-Orange-700x700.png?v=1700308595&width=460)

![Polymaker Polyterra PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/PolyTerra-Cotton-White3.png?v=1700308595&width=460)

![Polymaker Polyterra PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/PolyTerra-Candy-700x700.png?v=1700308595&width=460)

![Raise3D Premium PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-PremiumPLA-Red-2-Cardboard-Spool.jpg?v=1667612040&width=460)

![Raise3D Premium PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-PremiumPLA-Yellow-2-Cardboard-Spool.jpg?v=1667612040&width=460)

![Raise3D Premium PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-PremiumPLA-Blue-2-Cardboard-Spool.jpg?v=1667612040&width=460)

![Raise3D Premium PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-PremiumPLA-Orange-2-Cardboard-Spool.jpg?v=1667612040&width=460)

![Raise3D Premium PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-PremiumPLA-Grey-2-Cardboard-Spool.jpg?v=1667612040&width=460)

![Raise3D Premium PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-PremiumPLA-Black-2-Cardboard-Spool.jpg?v=1667612040&width=460)

![Raise3D Premium PLA - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-PremiumPLA-White.jpg?v=1668293302&width=460)

![Shining3D Einstar 3D-Scanner - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Einstar-3D-Scanner.png?v=1700308061&width=460)

![Shining3D Einstar 3D-Scanner - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/Einstar-3D-Scanner_1.jpg?v=1700308061&width=460)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D_3D-Printer_Pro3.jpg?v=1760088767&width=460)

![Bundle: Raise3D Pro3 3D Dual-Extruder + HUK - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/files/Raise3D-Pro3-HUK-Bundle-1-1-Shop.jpg?v=1760088767&width=460)

![Raise3D Pro2 Plus 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/RAISEPRO2PLUS_33617f44-4994-4eb9-a103-aec56d06d7d3.jpg?v=1700335460&width=460)

![Raise3D Pro2 Plus 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/Raise3DDiscountIDEE_1.png?v=1700335460&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608884_gold05kg.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608880_gold.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608849_silber_82d1caf7-3bb0-4689-98bc-9cf26224a4af.jpg?v=1673908217&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608829_silber.jpg?v=1673908204&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608850_schwarz.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608823_schwarz.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608855_weiss.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608824_weiss.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608853_blau.jpg?v=1673910697&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608826_blau.jpg?v=1673910697&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608854_gruen.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/gruen.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608882_gelb_05kg.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608878_gelb1kg.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608883_braun05kg.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608879_braun1kg.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608885_pink05kg.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608881_pink.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608843_Natural_4e5b4dc9-4132-41e7-9aba-e30c71c742c2.jpg?v=1673908109&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608845_transparentorange_96bb4088-6789-40f7-8be8-bca9113105cc.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608820_transparentorange1kg_40c1e991-e09d-40bc-8cc1-2a93e28f8b7b.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608846_transparentrot_dd3eab1a-c01c-438f-b45c-8205fbedaa33.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608819_transparentrot_d2ba4a55-670e-431a-886c-ad2cadd49f3e.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608847_transparentblau.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608818_transparentblau1kg.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608848_transparentgruen_cdee50fb-9916-466f-a855-c77ba415d1c6.jpg?v=1673910596&width=460)

![Flashforge PLA - 1.75mm - 500g/1000g - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/608817_transparentgruen1kg_f3bc53dc-0599-4679-a885-0e4117b847bb.jpg?v=1673910596&width=460)

![Polymaker PolyTerra PLA Dual 1,75mm 1kg - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/PolyTerra-Dual-PLA_1-75mm_1kg_Foggy-Purple-Purple_600x600_d536672b-71f5-4400-a9af-a045bd9a226d.jpg?v=1700312155&width=176)