3D printing services

Enter innovation with our 3D printing production line. We specialize in professional project analysis and consulting to bring your ideas to life.

Get a free quote now:

Contact No.

+49 (0) 69 - 678 382 24

Email ID

info@3dmaterial-shop.de

Our 3D services

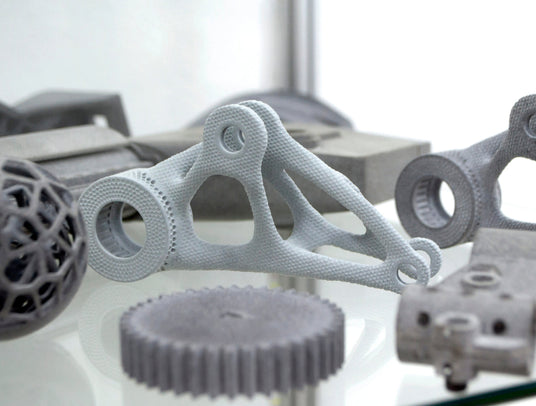

3D printing

Discover the limitless world of 3D printing.

Experience the ease of 3D printing with us. Work with us to bring your project to life using the latest 3D printing technologies. We specialize in FDM, SLS, SLA, DMLS and PolyJet and offer various options to meet your needs. With a state-of-the-art 3D printer fleet and a team of experienced engineers, we guarantee the highest quality for your 3D prints.

Contact us today to find out the cost of 3D printing.

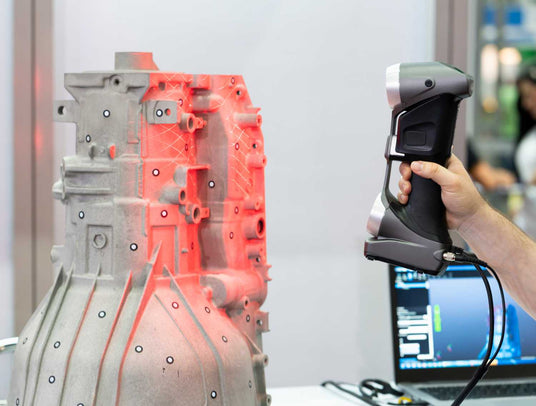

3D scanning

Use cutting-edge 3D scanning technologies for unprecedented precision.

Our scanners boast an accuracy of up to 0.05 mm and use the latest technologies. Whether your project involves small, complex models or larger structures with a span of 0.05 m to 4 m, our 3D scanning capabilities are just right for you.

Capture the essence of every detail as we deliver carefully measured 3D models of virtually any object. These prints can be easily transferred to CAD programs for further modification and optimization before being 3D printed.

Advice

Our 3D printing technology consulting service ensures a tailored approach to meet your requirements. The process starts with understanding your needs and identifying the most suitable 3D printing technology. We then carefully select the optimal materials and printing parameters. The culmination of our service is the creation of a free estimate for the 3D printing service in your chosen technology.

Post-processing

To enhance the visual and tactile appeal of 3D printing and increase its overall value, we offer a range of chemical and mechanical processing options. Our modeling services include folding or adhesive prints, chemical treatments, mechanical finishing, UV exposure for resin prints, spin polishing (SLS), surface staining (SLS), mud and sanding, and painting and varnishing. These techniques ensure that your 3D prints meet and exceed your expectations.

3D modeling

The process of CAD model creation starts with receiving technical documentation from the client. Then a digital 3D model is generated, explicitly tailored for future printing using the chosen 3D printing technology. Commonly used formats for creating digital models include IGS, OBJ, STP, X_T, STL, AutoCAD, CATIA, STEP, REVIT, IronCAD, FreeCAD, SAT, PARASOLID, NX, Blender, ACIS, 3DMAX, CREO, ArchiCAD, IGES, Inventor, SolidEdge, SolidWorks, Rhino, ThinkDesign, ZW3D, SketchUp and various others.

3D printing technologies

Selective laser sintering (SLS)

Share information about your brand with your customers. Describe a product, make announcemSelective laser sintering (SLS) is an additive manufacturing technique in which a laser selectively fuses powdered materials, such as polymers or metals, layer by layer. Known for its versatility, SLS enables the creation of complex and functional prototypes and durable end-use parts. The process offers various material options, contributing to its popularity across numerous industries. For example, SLS can be used in the automotive industry to produce durable components such as engine mounts or intricate interior parts, proving its adaptability.ents, or welcome customers to your store.

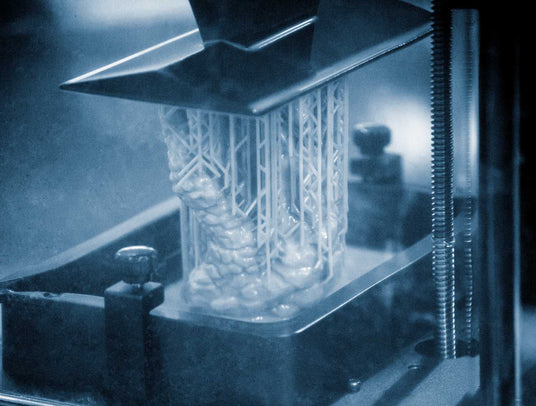

Stereolithography (SLA)

Stereolithography (SLA) uses a high-precision UV laser to cure liquid resin layer by layer, resulting in exceptionally detailed and precise 3D prints. SLA is known for its ability to produce smooth surfaces and intricate geometries, and is suitable for applications that require high precision, such as developing detailed prototypes and complex models.

Stereolithography (SLA) is widely used in the medical field to create detailed anatomical models for surgical planning. Surgeons can use these precise 3D printed models to improve their understanding of complex procedures before entering the operating room.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a widely used 3D printing technology that melts and extrudes thermoplastic filaments layer by layer. Known for its accessibility and cost-effectiveness, FDM is suitable for prototyping, concept models, and production of functional parts. Its straightforward process and material diversity make it the first choice for various applications. FDM is widely used in the production of architectural models. Architects and designers use FDM to bring their designs to life and create scale models with precision and cost-effectiveness.

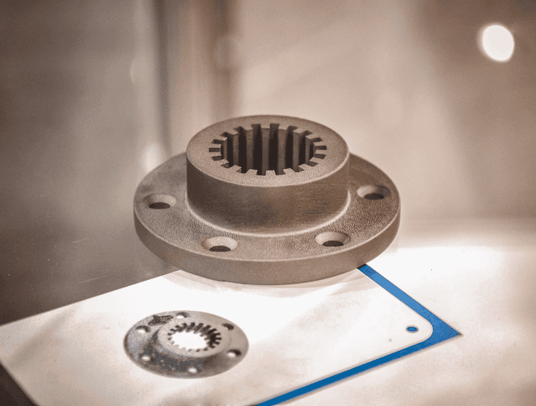

Direct metal laser sintering (DMLS)

Direct metal laser sintering (DMLS) is an advanced metal 3D printing technique that uses a laser to selectively sinter and fuse metal powder. This technology creates robust and highly precise metal components, making it invaluable in industries such as aerospace and healthcare, where complex metal parts are critical to performance and functionality. Jet engine components, which emphasize intricate designs and high-strength materials, can be efficiently manufactured using DMLS technology.

PolyJet printing

PolyJet technology takes a unique approach by using nozzles to release layers of liquid photopolymer that are instantly cured with UV light. The ability to print multiple materials simultaneously makes PolyJet ideal for producing intricate, multi-colored, and highly detailed models. Its versatility and ability to reproduce a wide range of material properties contribute to its application in fields that require visual realism. It is particularly suited to consumer product design. In the consumer electronics industry, for example, PolyJet can be used to create realistic prototypes of devices such as smartphones, allowing designers to evaluate both form and function before mass production.

Multi-Jet Fusion (MJF)

Multi-Jet Fusion (MJF) is an innovative 3D printing technology that uses active ingredients and infrared light to fuse layers of powder, resulting in robust and functional parts. Known for its speed and efficiency, MJF is suitable for both rapid prototyping and manufacturing applications. Its precision and ability to produce intricate structures make MJF a versatile choice for various industries seeking efficient, high-quality production solutions. It is becoming increasingly important in the manufacture of customized medical implants. For example, MJF can be used to efficiently produce hip or knee implants tailored to a patient's anatomy, optimizing fit and functionality.

![Polymaker PolyTerra PLA Dual 1,75mm 1kg - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/PolyTerra-Dual-PLA_1-75mm_1kg_Foggy-Purple-Purple_600x600_d536672b-71f5-4400-a9af-a045bd9a226d.jpg?v=1700312155&width=176)