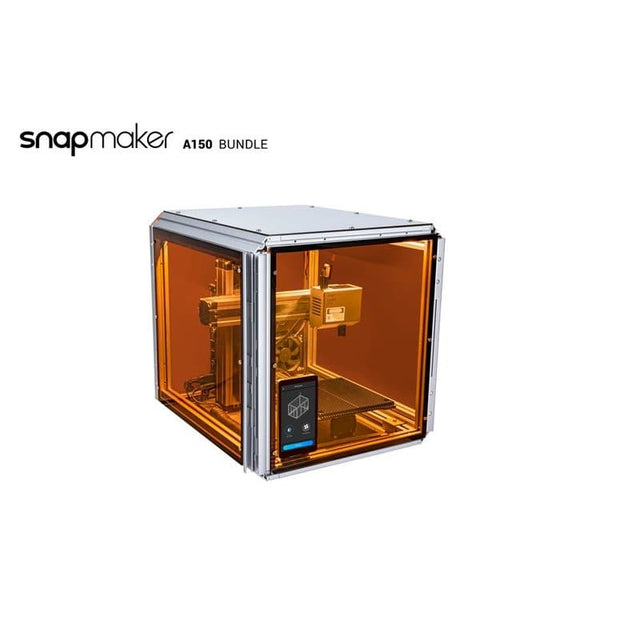

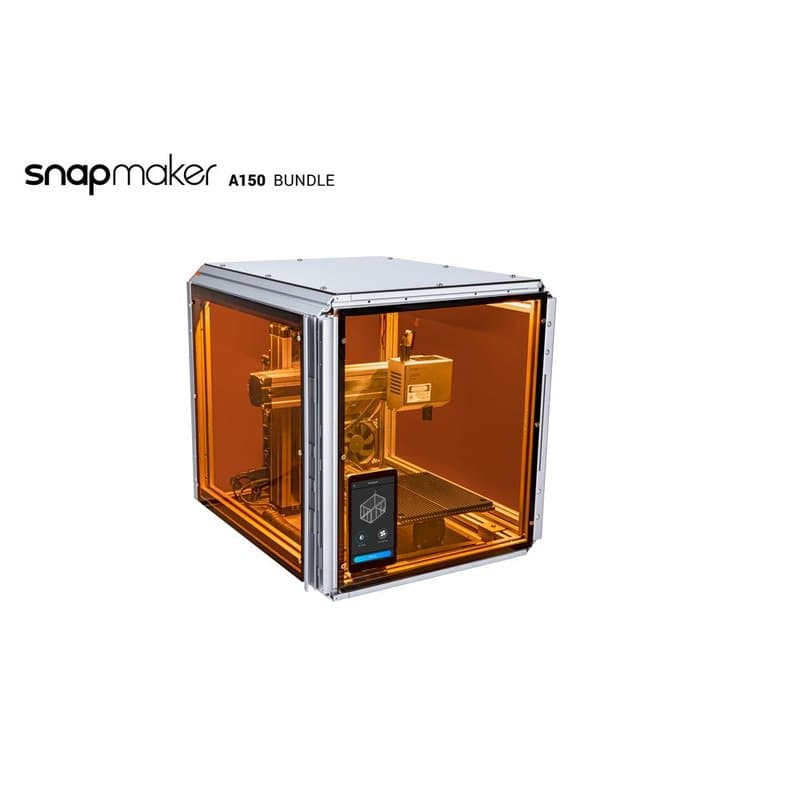

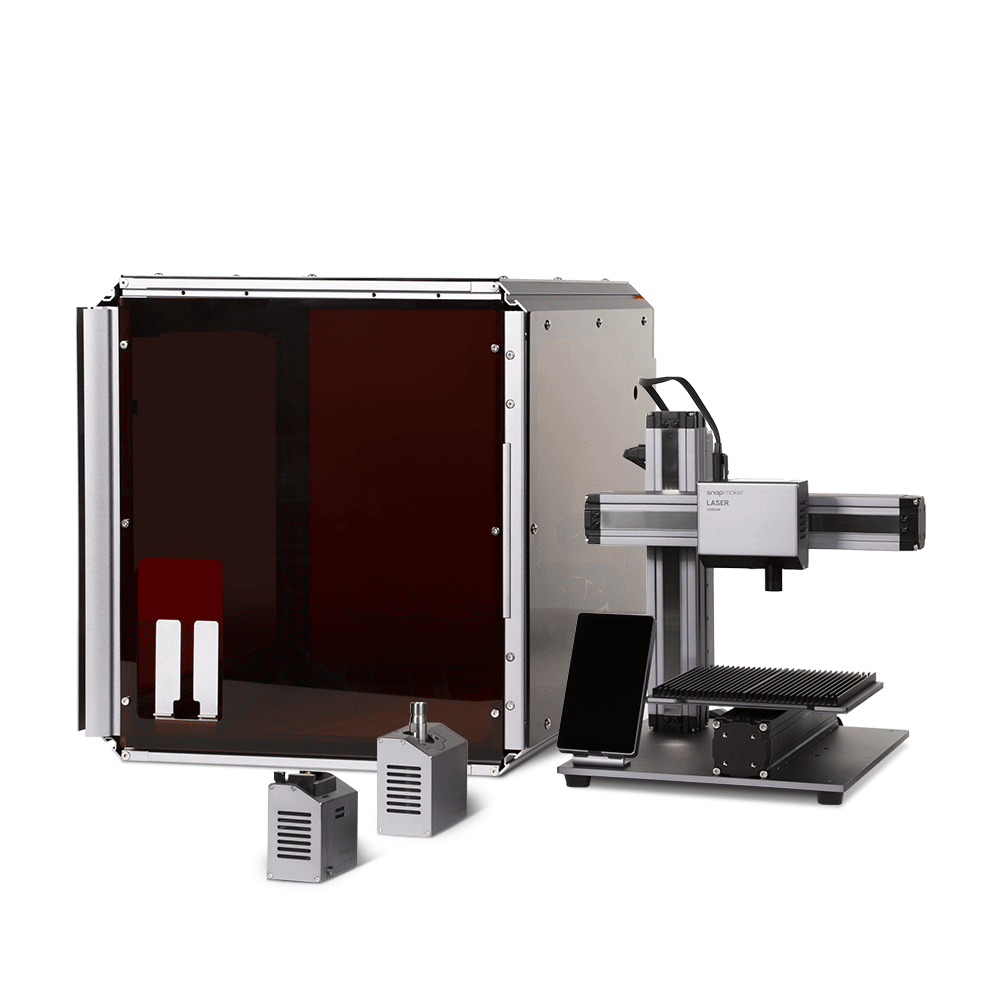

Snapmaker 2.0 Modular 3-in-1 3D printer including housing

Snapmaker 2.0 Modular 3-in-1 3D printer including housing - A250T is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

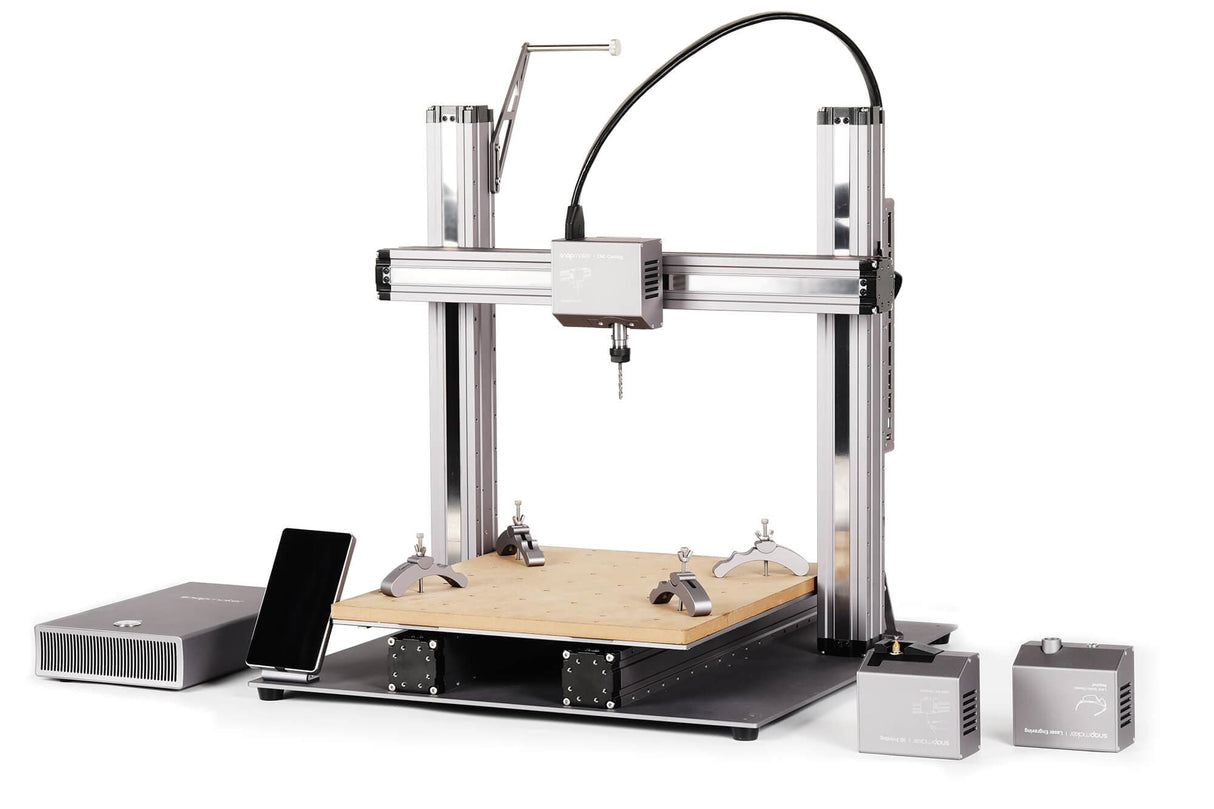

Snapmaker 2.0 Modular 3-in-1 3D printer

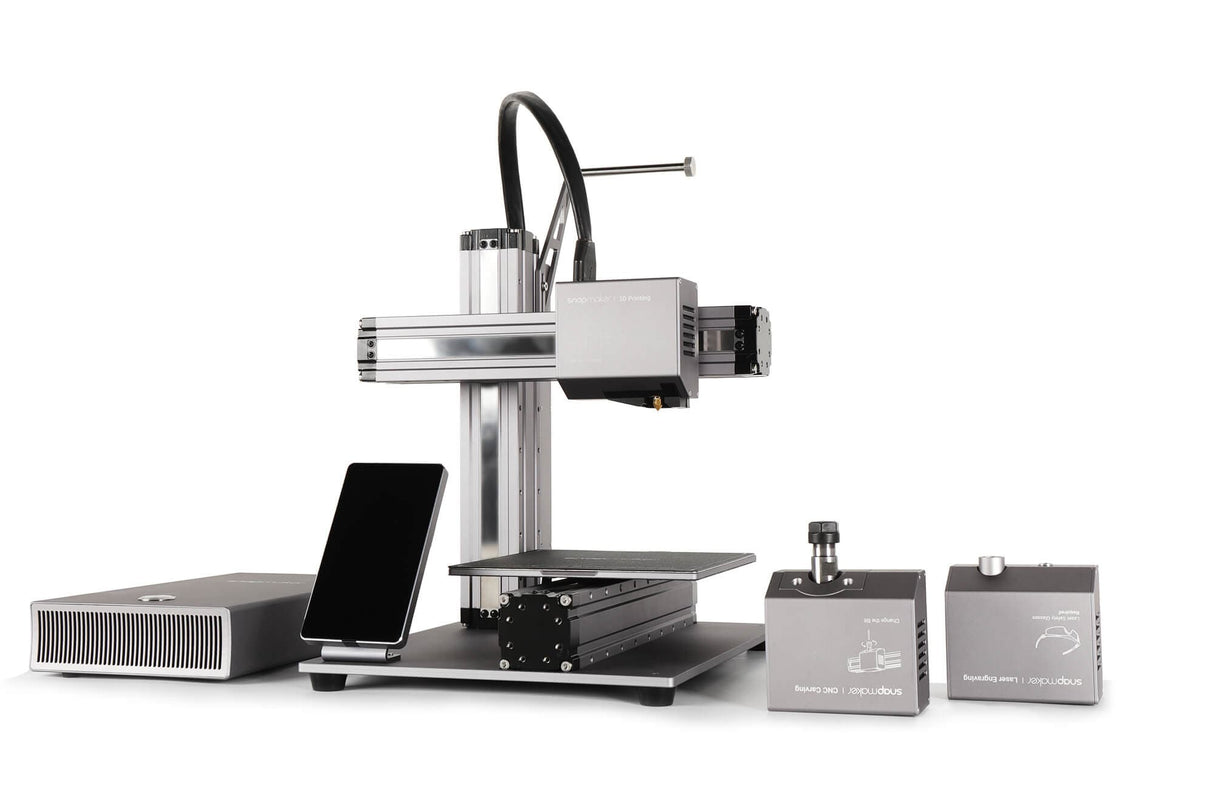

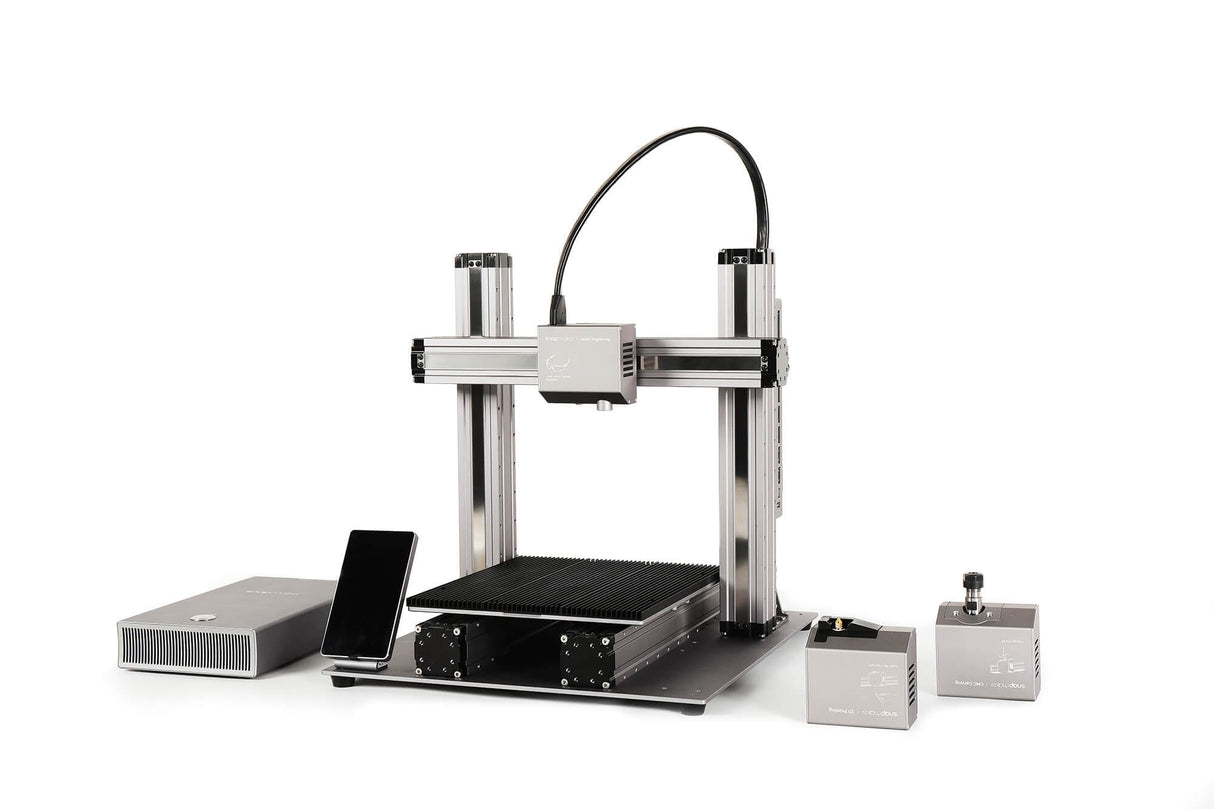

3D printer, laser engraving/cutting and CNC carving in one device

The Snapmaker 2.0 is a modular 3-in-1 3D printer and, in addition to 3D printing, also offers its users the option of laser engraving/cutting and CNC carving functions. So nothing stands in the way of you to turn your projects into reality.

3 possibilities in one device - Snapmaker 2.0

Snapmaker 2.0 are modular 3-in-1 D printers and make 3D printing, laser engraving/cutting and CNC carving possible in one device. Snapmaker 2.0 is smarter, faster, bigger and more powerful than ever. It's a new generation of 3-in-1 3D printer that comes with everything you need!

3D printing

Snapmaker 2.0 modular 3-in-1 3D printers are ideal for beginners, for hobbyists who prefer more customized options, as well as for engineers and designers who want to print large objects or precise parts with excellent print quality. From general purpose applications to objects with specific mechanical properties such as durability, toughness and flexibility, you can print almost any creative project with the Snapmaker 2.0.

Laser engraving and cutting

Commercially available 3D printers only create 3D prints. The Snapmaker can quickly change its functionality with the interchangeable modules, comparable to changing the lens of a camera. A wide variety of materials can be easily processed with the laser module. A variety of materials you find in everyday life are laser engraveable or cuttable, including paper, plywood, leather, acrylic, cardboard, paper, fabric, and even food like cookies and coconuts!

CNC carving

You can even use the Snapmaker 2.0 as a CNC router to create precise 2.5D and 3D objects. It has a significantly larger working range and a higher working speed than the original model. The CNC carving module is ideal for precise carving or cutting of hard materials. With the Snapmaker 2.0 you are not limited by plastic or soft material options and you can use the following materials for your creative projects: hardwood, PCB, acrylic, POM, carbon fiber board and many more materials.

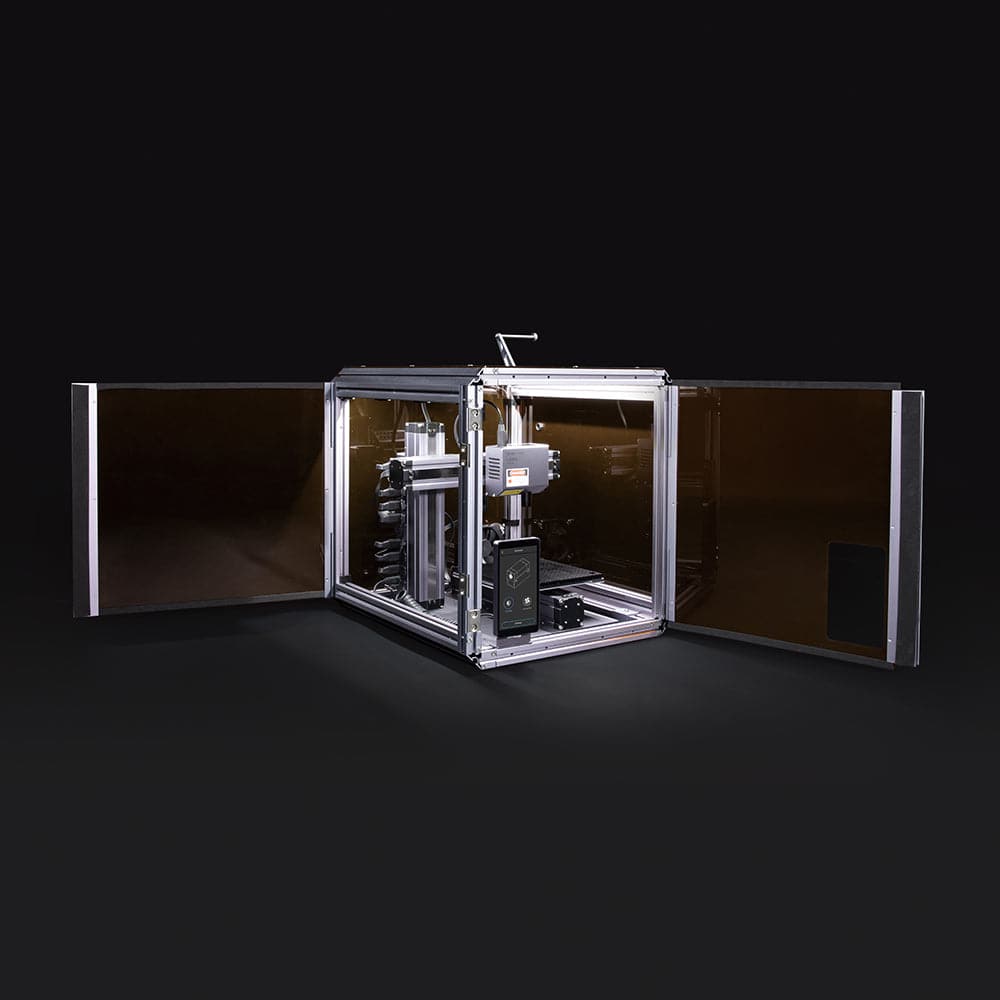

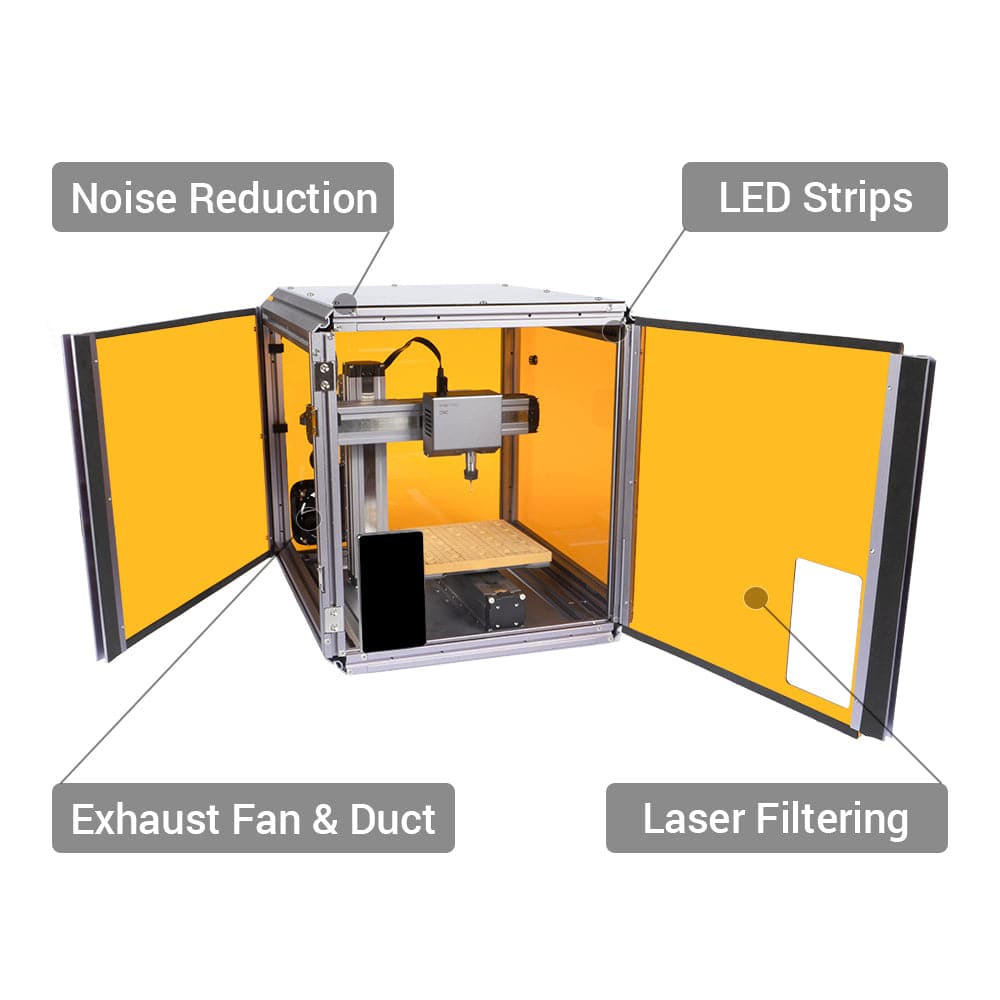

Note: This article is a bundle consisting of a 3-in-1 3D printer and housing (enclosure). As a European dealer based in Germany, we are not allowed to sell the device individually and due to security guidelines we always have to sell an enclosure as well. We ask for your understanding.

Modular design - one printer with many possibilities

Modular 3D printer

Imagine a 3D printer that you can upgrade and customize. The Snapmaker is more than just a series of machines. It is a system of powerful modules and add-ons whose features you can use just by getting the new modules or kits.

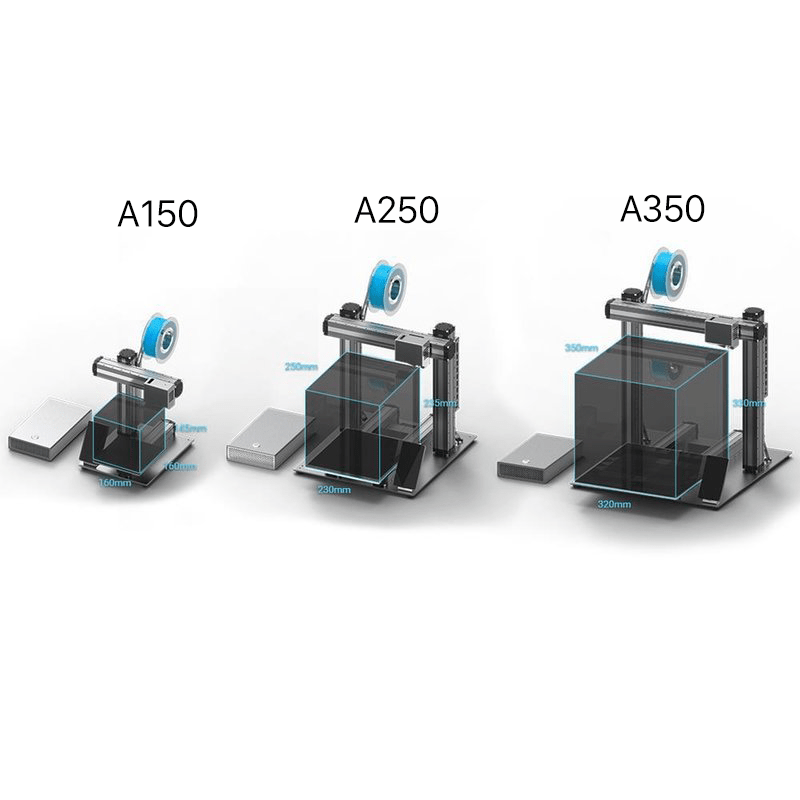

Large work area

The Snapmaker 2.0 is available in three models: A150, A250 and A350. You can make large prototypes or multiple smaller objects in one operation. The A350 offers the largest build volume at 320 x 350 x 330mm, followed by the A250 at 230 x 250 x 235mm and the A150 at 160 x 160 x 145mm.

Add ons

As an innovative Snapmaker user, you can further increase your creative diversity with a variety of add-ons to personalize your Snapmaker 2.0. For a larger number of applications, housing, lighting, a hand wheel, an emergency stop button and a camera will be available for pre-order in the future (not included with this article).

Powerful controller

The Snapmaker 2.0 supports various tool heads, add-ons, multiple linear modules and other functions with just one controller. An important reason for this is that the CAN (Controlled Area Network) bus extension solution, which is widespread in vehicle automation, was used in an innovative way. Instead of adding more connectors and making a bigger control board with countless cables, the controller has been upgraded by providing universal ports, multiport adapters and a CAN hub to add additional CAN bus connectors. Using the CAN bus protocol, the controller is able to connect all modules and add-ons in the Snapmaker 2.0 system. Each module and add-on contains a chip for receiving all transmitted messages and behaving accordingly. This allows for easy modification and inclusion of additional ports and controls in the future.

Future expansion

The modular Snapmaker 2.0 3D printers can be transformed into even more powerful machines with the upcoming more powerful laser module, third-party spindle compatibility package, rotary module (can be used for A250, A350) and longer linear modules! The brand has made it worth investing in your own fabrication tools by bringing more modularity to desktop fabrication tools.

High quality from Snapmaker

all metal

All Snapmaker models are built to last. The Snapmaker 2.0 pushed the boundaries of all-metal construction even further. All modules and main components are made of high-strength metal. For example, both the controller board and the power supply use aluminum alloy cases for better heat dissipation; the original POM rollers are upgraded to steel rollers for higher load capacity and rigidity.

High quality

The aerospace-grade aluminum alloys are processed into precise, reliable parts of Snapmaker modules after a series of processing steps. Each manufacturing process is strictly controlled and each part is meticulously crafted. The Snapmaker 2.0 not only looks premium, but also delivers consistently high performance.

high precision

With the Snapmaker 2.0, the high-precision, computer-controlled tools can be used without any problems on any desk. Because only the best quality components are integrated, it has high accuracy and repeatability, allowing it to 3D print, engrave and cut objects in high resolution.

Ease of use in all areas

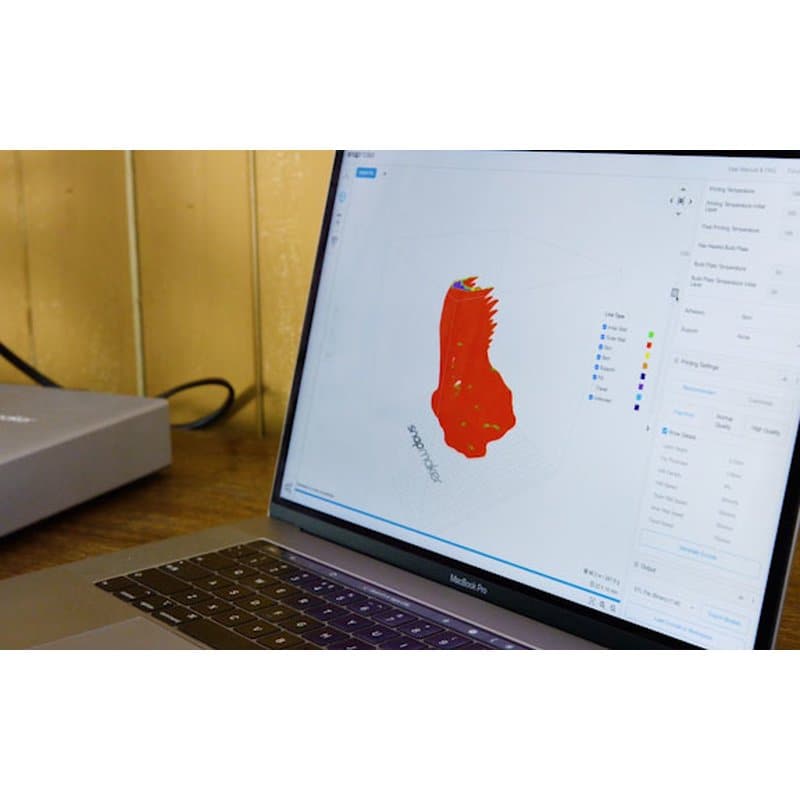

3-in-1 software

The 3-in-1 software, Snapmakerjs, is tailor-made for your Snapmaker machines - one powerful software for all your tasks. It has been iterated through 18 versions over the last year and a half, adding features such as printing, engraving, cutting and carving multiple models, SVG editing, relief carving, and multiple language support. Through rapid iterations, many general requests from the community have been incorporated. With a plugin system, API, and tutorials, Snapmakerjs allows you to easily add new functionality to existing modules. You can also develop new functions for your custom modules.

WiFi connectivity

With the WLAN function and the USB port, you can easily connect your Snapmaker 2.0 to any configuration. You can upload designs via WiFi or USB flash drive and print with the push of a button. In addition, you can update the firmware directly via WiFi.

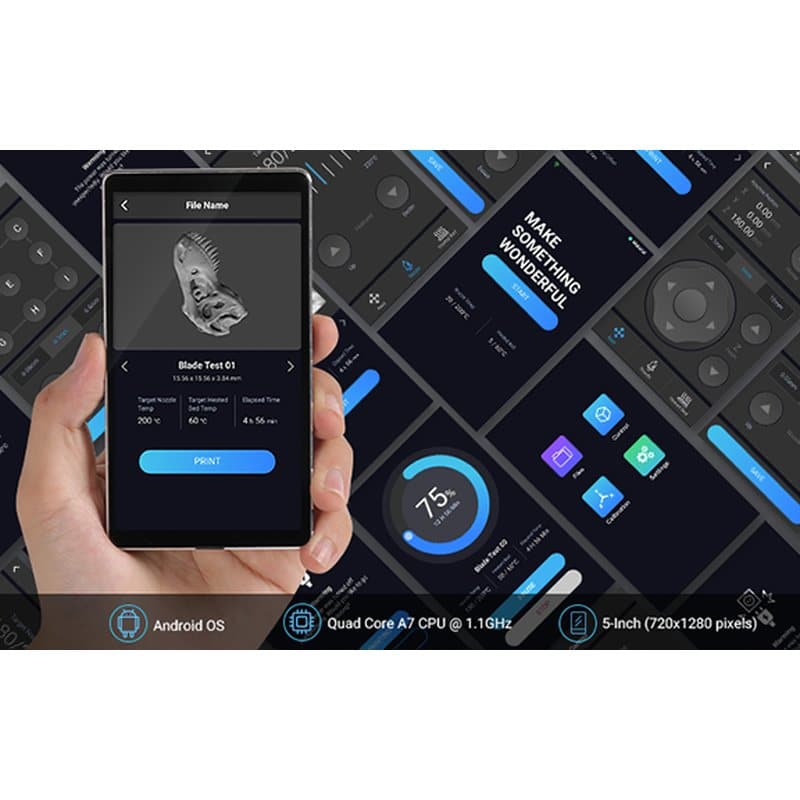

Intelligent touch screen

Traditionally, machines like 3D printers, laser cutters, and CNC routers didn't pay enough attention to the human-machine interface (HMI). The Snapmaker 2.0 comes with an intelligent touchscreen that simplifies the workflow of your daily projects and allows you to manage the most frequently used tasks right from the touchscreen. Similar to a smartphone, this 5-inch (720 x 1280 pixels) articulated touchscreen is equipped with a Quad Core A7 CPU at 1.1GHz running on the Android OS, providing a smooth and fast interface.

Recover from power failure

You no longer have to worry about power outages. The Snapmaker 2.0 automatically detects a power failure and then picks up exactly where it left off. You can restore any project and get perfect printing, engraving, cutting and carving results every time.

Easy construction

When you build something, you know how it works. Building a working 3D printer sounds like a daunting task, let alone building a laser cutter or CNC router. Snapmaker assures you that you will enjoy assembling your own Snapmaker 2.0 and find that this is the best kit you have ever assembled.

Snapmaker 2.0 3D printing highlights

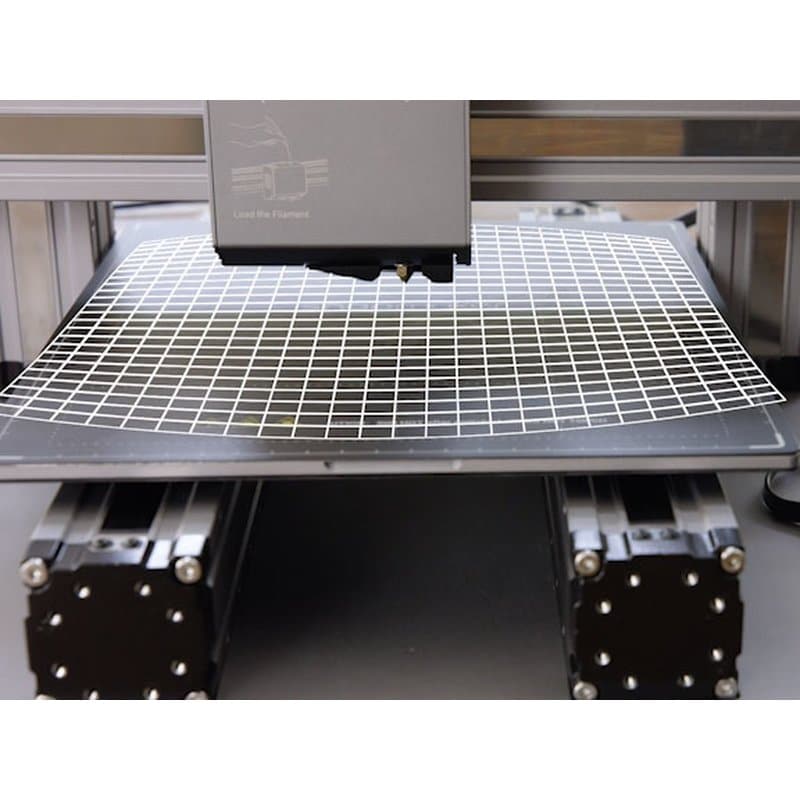

Automatic leveling

Leveling the bed is a tricky process, especially with a large heatbed and inexperienced users. To make leveling the bed easier, an automatic leveling function has been added. An inductive sensor can scan the bed in a raster and apply mesh-based compensation, ensuring you print on a flat bed every time without going through a complicated process.

Filament runout recovery

Equipped with a filament run-out sensor, those who want to print a large object can now print without fear. This prevents unfinished prints and "air pressure". As soon as the sensor detects that the filament has run out, the touchscreen reports that a new filament needs to be inserted and you can resume printing immediately.

Improved cooling system

With the Snapmaker 2.0 you can print objects with deep overhangs and get a smoother surface! Cooling is just as important in FDM 3D printing as heating. For the Snapmaker 2.0, the cooling system has been redesigned to cool the print in the most efficient way.

Flexible platform

Removing a print is now easier than ever. Simply lift and flex the platen, no matter the size or shape of your print. Because the heatbed uses a magnetic design, you can easily remove and put the printing plate back, or place it against the laser cutting or CNC carving worktable in one change minutes.

Laser Highlights

Integrated camera

The integrated camera allows you to preview your design with the material you are using. You can edit your design and position it exactly where you want it. What you see is what you get!

Faster engraving

Faster is better. Line Mode (Normal Quality) has been added to give you a quick engraving option for grayscale images. This feature will save you hours of engraving large grayscale images. The quality is still very good compared to the original dot mode (High Quality).

Aluminum grid table

The aluminum grid table is specially designed to prevent bed damage caused by defocusing of the laser beam during cutting. It is detachable and super strong.

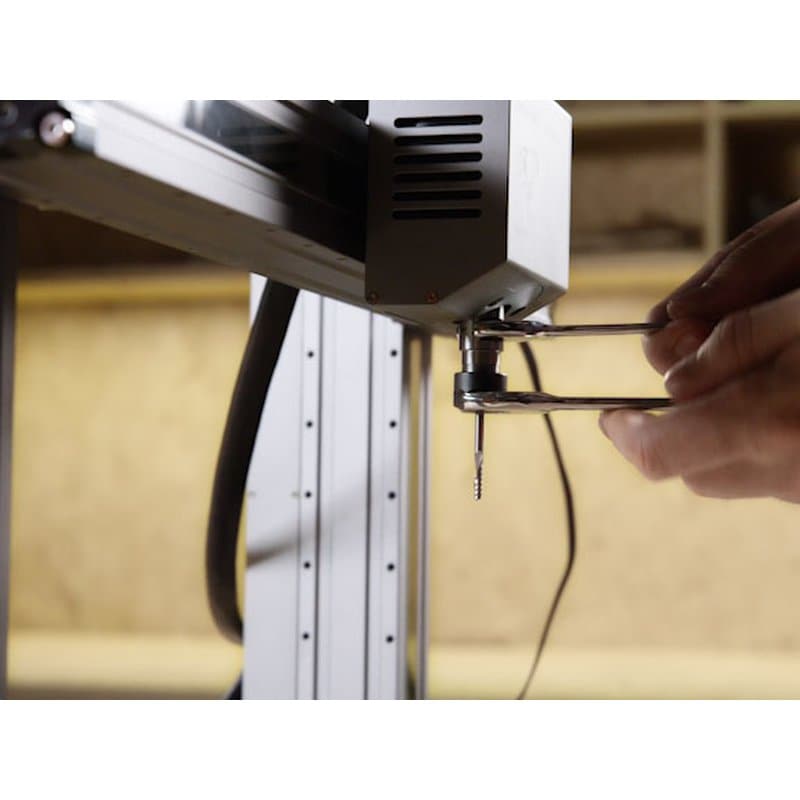

CNC highlights

ER11 collet

The Snapmaker 2.0 has a completely revised CNC module. When using the standard ER11 collet, it guarantees better concentricity, which allows for faster CNC cutting speed and a larger step down, saving you significant time. The diameters of the bits of the carving and cutting tools range from 0.5 mm to 6.35 mm.

waste board and clamp sets

Each Snapmaker 2.0 comes with an MDF waste board. It is detachable, protecting the bed from damage and providing a smooth and flat surface for precise CNC carving. Also, you can use the included aluminum clamp sets to fix the materials more easily and reliably.

dust resistance

The Snapmaker 2.0 linear module has been upgraded for easy maintenance. Work spindle, driver chip and precision parts are fully enclosed in the aluminum alloy cases. This eliminates the problem of dirt build-up, resulting in improved durability.

A150

Heated bed: up to 110°C

printer size

- 160 x 160 x 145 mm (3D printing)

- 160 x 160 mm (laser engraving/cutting)

- 160 x 160 x 90 mm (CNC carving)

A250

Heated bed: up to 100°C

printer size

- 230 x 250 x 235 mm (3D printing)

- 230 x 250 mm (laser engraving/cutting)

- 230 x 250 x 180 mm (CNC carving)

A350

Heated bed: up to 80°C

printer size

- 320 x 350 x 330 mm (3D printing)

- 320 x 350 mm (laser engraving/cutting)

- 320 x 350 x 275 mm (CNC carving)

General technical data

- Frame material: aluminum alloys

- Connectivity: WiFi, USB cable, USB flash drive

- Touchscreen: 5?, Android OS, Quad Core A7 CPU @ 1.1GHz

- Software: Snapmaker Luban

- Supported file types: stl, obj, svg, jpeg, png, more to come

- Supported operating systems: MacOS, Windows, Linux

- Rated Power: 320W

3D printing

- Layer resolution: 50 - 300 microns

- Nozzle Temperature: Up to 275°C

- Supported Materials: PLA, ABS, TPU, PETG, Wood Filled PLA, more to come

Laser engraving and cutting

- Camera: Integrated camera

- Laser: 1600mW 450nm laser diode

- Wavelength: 450nm

- Security class: Class 4

- Supported Materials: Wood, Leather, Plastic, Cloth, Paper, Opaque Acrylic, more being tested

CNC carving

- Shaft diameter: 0.5mm-6.35mm (0.02-0.25 inches)

- Spindle speed: 6,000 - 12,000 rpm

- Supported Materials: Wood, Acrylic, PCB, Carbon Fiber Board, Jade, more being tested

Payment & Security

Payment methods

Your payment information is processed securely. We do not store any credit card information and do not have access to your credit card information.

Zertifizierte Sicherheit & Käuferschutz

Vertrauen Sie auf echte Bewertungen und zertifizierte Sicherheit beim Online-Kauf.

Price on request – your personal offer!

Use the " Price on request " function and get a

tailor-made offer for your desired product. We offer you the opportunity to request an individual price and thus make a unique bargain.

Contact us now for your individual offer!

![Snapmaker 2.0 Modularer 3-in-1 3D-Drucker - [3DMaterial-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Snapmaker-2-0-3-in-1-3D-Printer-with-Enclosure.png?v=1660781903&width=1214)

![Snapmaker 2.0 Modularer 3-in-1 3D-Drucker mit Gehäuse - [3DMaterial-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Snapmaker-2-0-3-in-1-3D-Printer-with-Enclosure-A250.png?v=1660781918&width=1214)

![Snapmaker 2.0 Modularer 3-in-1 3D-Drucker mit Gehäuse - [3DMaterial-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Snapmaker-2-0-3-in-1-3D-Printer-with-Enclosure-A250-80019-27044_1.png?v=1660781924&width=1214)

![Snapmaker 2.0 Modularer 3-in-1 3D-Drucker mit Gehäuse - [3DMaterial-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Snapmaker-2-0-3-in-1-3D-Printer-with-Enclosure-A250-80019-27044_4.png?v=1660781934&width=1214)

![Snapmaker 2.0 Modularer 3-in-1 3D-Drucker mit Gehäuse - [3DMaterial-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Snapmaker-2-0-3-in-1-3D-Printer-with-Enclosure-A250-80019-27044_5.png?v=1660781946&width=1214)

![Polymaker PolyTerra PLA Dual 1,75mm 1kg - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/PolyTerra-Dual-PLA_1-75mm_1kg_Foggy-Purple-Purple_600x600_d536672b-71f5-4400-a9af-a045bd9a226d.jpg?v=1700312155&width=176)