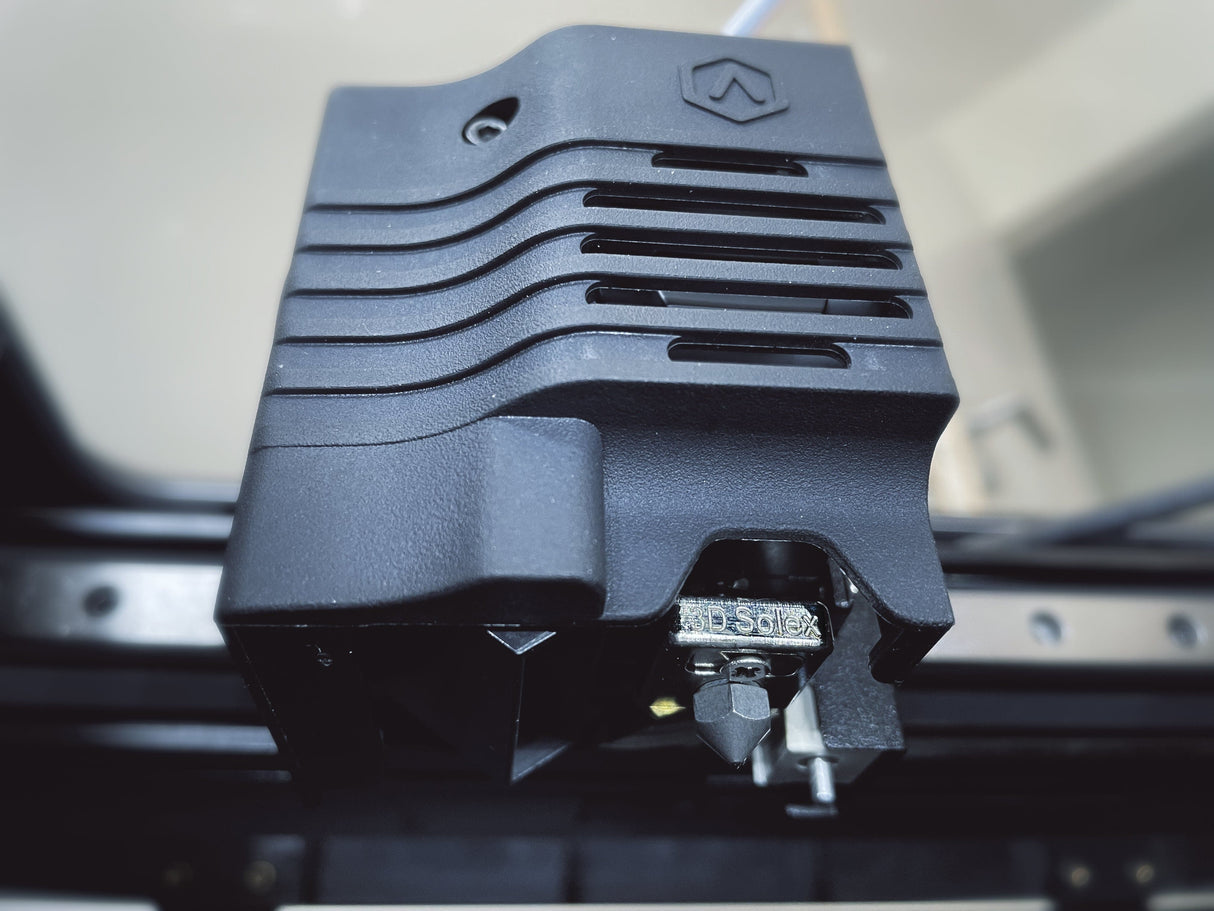

3D Solex Timeslicer Hotend Premium for Raise3D E2/Pro3 (0.40-0.60R-0.80)

3D Solex Timeslicer Hotend Premium for Raise3D E2/Pro3 (0.40-0.60R-0.80) is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Perfect upgrade for the original Raise3D E2 Hotend

Suitable for: Raise3D E2/Pro3 (can be mounted on both sides)

Scope of delivery:

1x Timeslicer Heatblock incl. Heatbreak (pre-assembled)

1x 04mm CHT Nozzle

1x 0.8mm CHT Nozzle

1x 0.6mm Ruby/Sapphire Nozzle

1x tool set

The smart Plug&Play alternative to the original Hotend

The 3DSolex Timeslicer upgrade hotend has been specially developed and optimized for the 1:1 replacement of Raise3D hotends of the E2 series.

Two sets are available:

Standard with a 0.40mm and a 0.80mm core heating nozzle for up to 4 times more filament flow compared to the normal hotend

Premium with an additional 0.60mm Ruby Everlast nozzle, which is specially designed for the long-term use of fiber-reinforced filaments.

The upgrade hotends use the original heating cartridge and the original temperature sensor. This means that nothing needs to be changed on the sensitive electronics, unlike products from other manufacturers.

When it comes to nozzles, 3DSolex offers a large selection of standard, special and custom sizes. Now also with CHT - Core Heating Technology - thanks to which up to 4x more plastic can be melted in the same amount of time. This enables previously unattainable printing speeds.

Standard nozzles:

0.25 / 0.40 / 0.60 / 0.80 / 1.00 mm (very similar to Raise3D offer)

Special nozzles with ruby insert for fiber-filled materials:

0.25/0.40/0.50/0.60/0.80/1.20mm

Special sizes:

0.10 / 0.15 / 1.50mm

This large selection naturally gives you even more flexibility.

This means you can print extremely fine structures with the small nozzles, achieve higher speeds with the large nozzles and use fiber-filled filaments permanently with the Ruby nozzles.

The advantages at a glance:

- Upgrade hotends can be exchanged 1:1 for Raise3D products (Plug&Play)

- CHT enables significantly higher melting performance and therefore higher printing speeds

- Significantly improved heat break, thus no more risk of filament jams between the hotend and the filament feed

- Optimized cooling, thus permanently high operating temperatures can be achieved

- Nozzles can be replaced more easily

- Large selection of nozzles

- Made in Norway, highest quality components and final assembly

- The temperature distribution is more even

- Identical height as the original hotend, so replacing a single hotend is no problem

- Easy nozzle replacement as brass (nozzle) is screwed into brass (block)

Payment & Security

Payment methods

Your payment information is processed securely. We do not store any credit card information and do not have access to your credit card information.

Zertifizierte Sicherheit & Käuferschutz

Vertrauen Sie auf echte Bewertungen und zertifizierte Sicherheit beim Online-Kauf.

Price on request – your personal offer!

Use the " Price on request " function and get a

tailor-made offer for your desired product. We offer you the opportunity to request an individual price and thus make a unique bargain.

Contact us now for your individual offer!

![3D Solex Timeslicer Hotend Premium für Raise3D E2 (0.40-0.60R-0.80) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Pack-shot-1HnAbzq9ve5u8h_1e18ad41-4b23-4814-b8d3-a17e70ae3fd2.jpg?v=1700336657&width=1214)

![3D Solex Timeslicer Hotend Premium für Raise3D E2 (0.40-0.60R-0.80) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Pack-shot-1HnAbzq9ve5u8h_1e18ad41-4b23-4814-b8d3-a17e70ae3fd2.jpg?v=1700336657&width=112)

![Polymaker PolyTerra PLA Dual 1,75mm 1kg - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/PolyTerra-Dual-PLA_1-75mm_1kg_Foggy-Purple-Purple_600x600_d536672b-71f5-4400-a9af-a045bd9a226d.jpg?v=1700312155&width=176)

![3D Solex Timeslicer Hotend Premium für Raise3D E2 (0.40-0.60R-0.80) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Pack-shot-1HnAbzq9ve5u8h_1e18ad41-4b23-4814-b8d3-a17e70ae3fd2.jpg?v=1700336657&width=640)