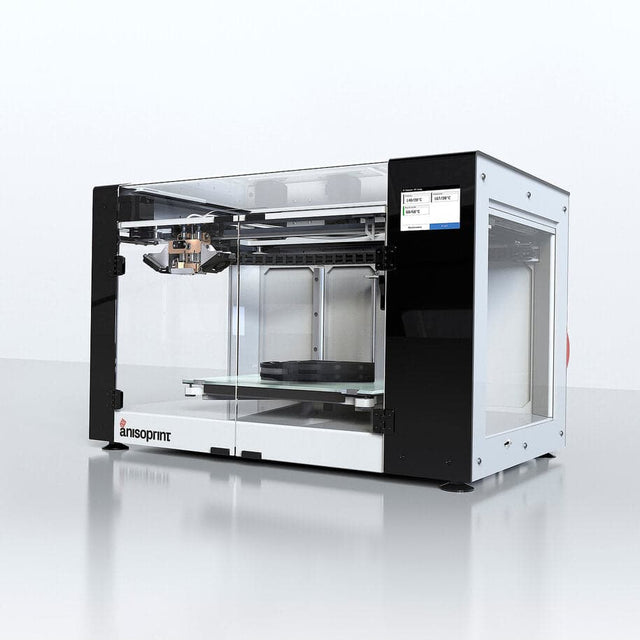

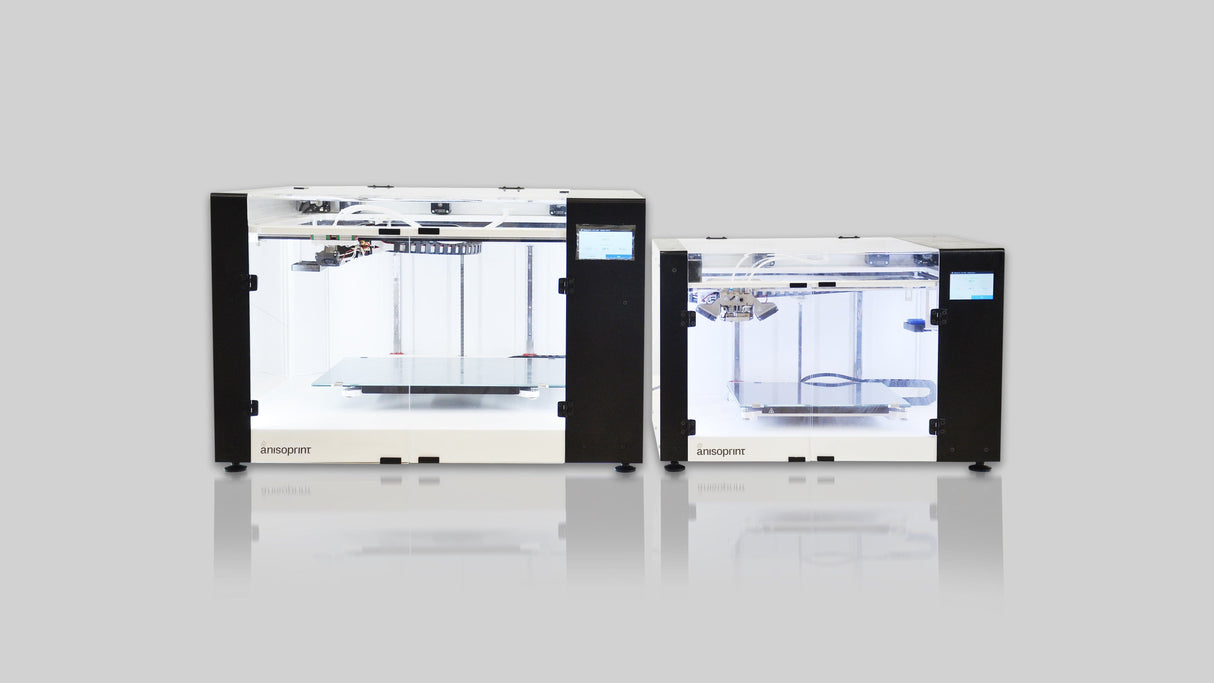

Anisoprint Composer A3 3D printer - industrial 3D printer with continuous fiber

Anisoprint Composer A3 3D printer - industrial 3D printer with continuous fiber is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

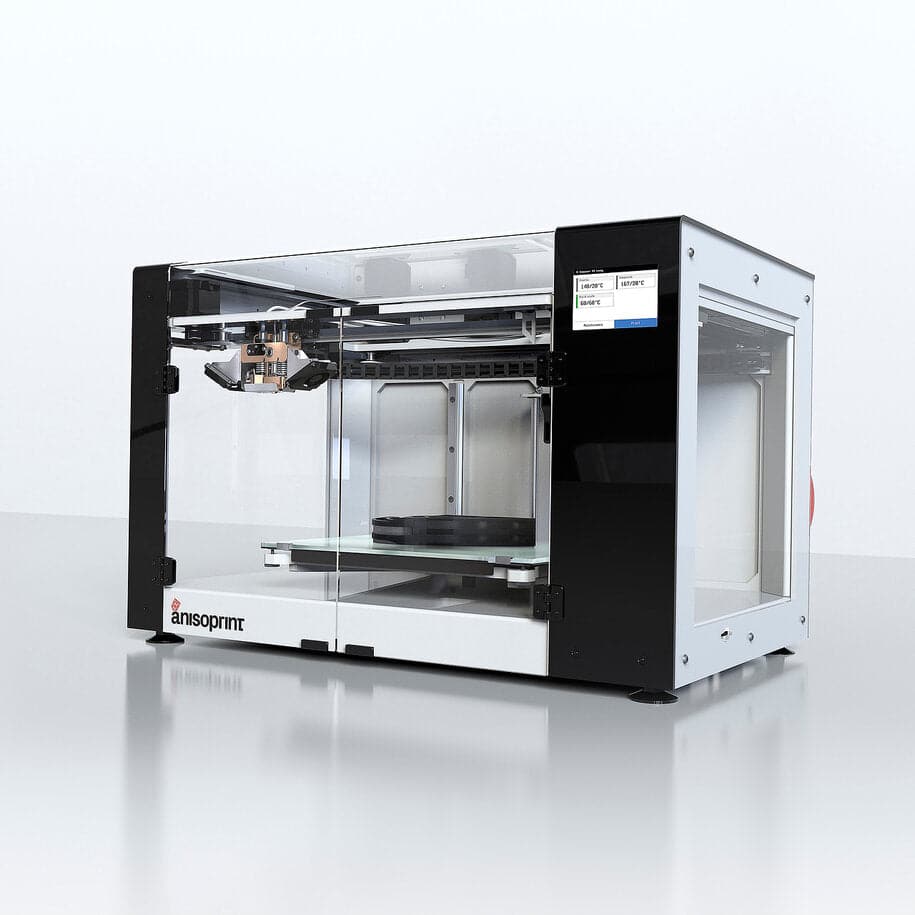

Anisoprint Composer A3 3D printer - industrial continuous fiber 3D printer

The Anisoprint Composer A3 3D printer works with both proprietary, patented CFC (Composite Fiber Coextrusion) technology and standard FFF 3D printing technology. The Anisoprint Composer A3 3D printer enables the production of optimized composite structures characterized by high physical and mechanical properties. End parts are stronger and lighter than parts of similar properties made with metal, thermoplastics, or non-optimized composites. In addition, they can be manufactured at a lower cost.

Features Composer A3

- FFF and CFC extruder

- LCD touch screen

- Two-nozzle system

- Removable print bed

- Strong yet lightweight prints

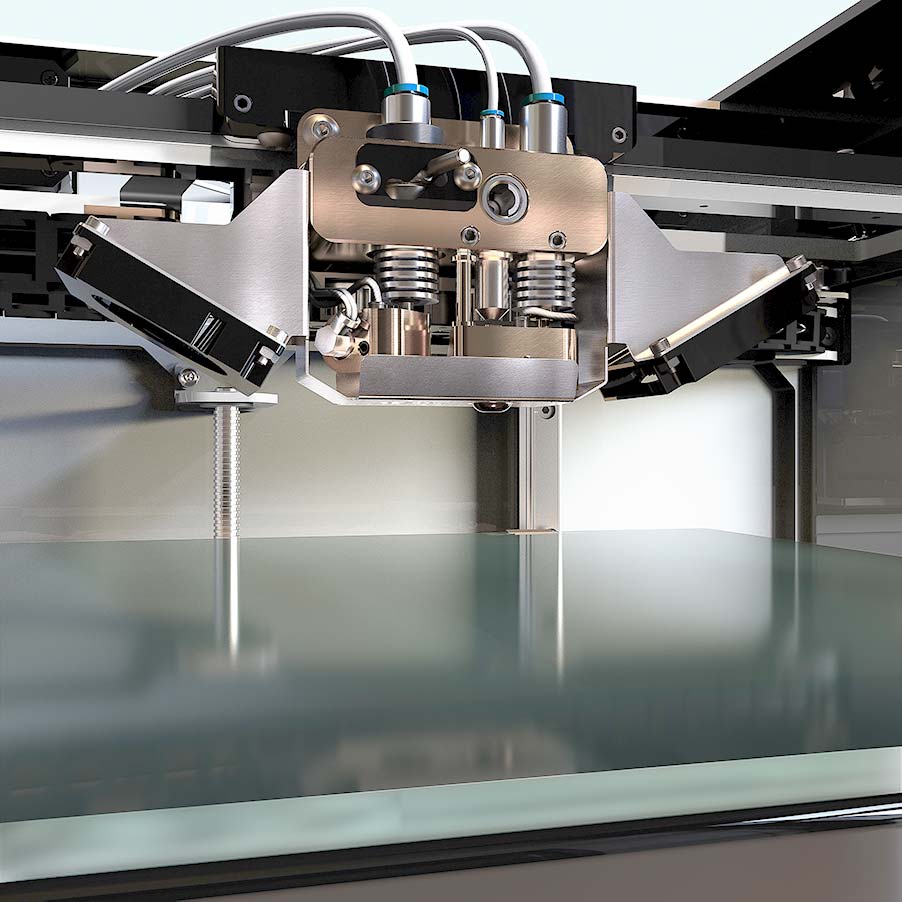

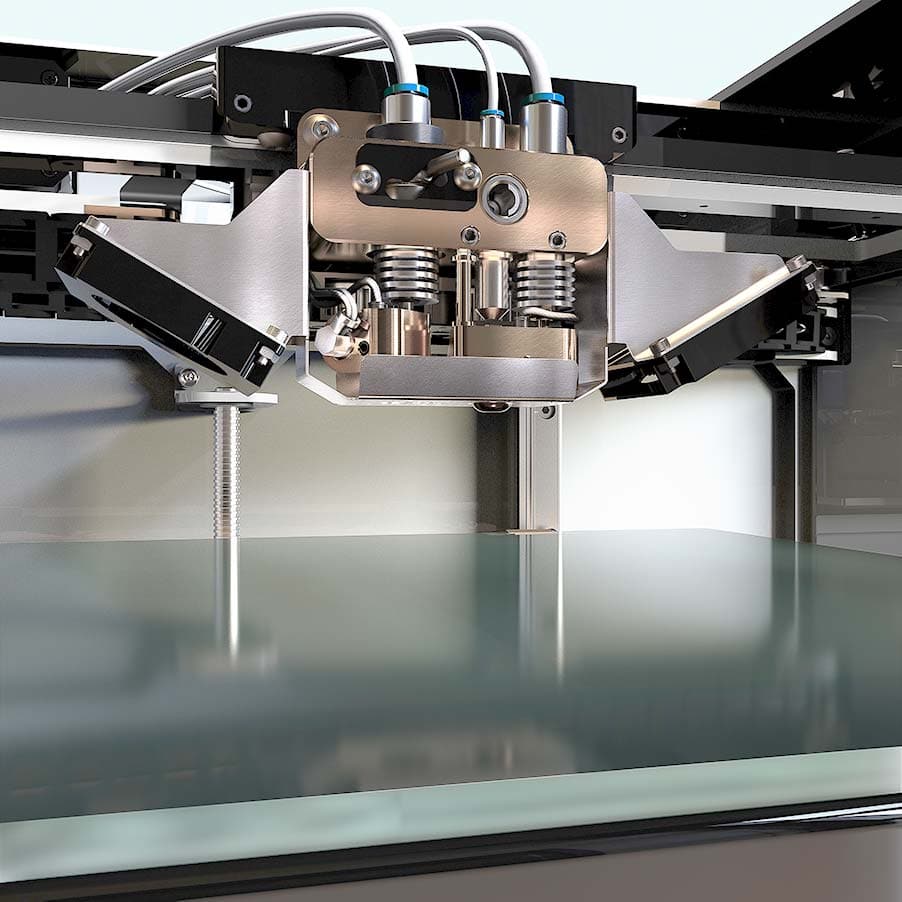

- CFC extruder with cutting device for reinforcement fibers

- Print bed size 420 mm х 297 mm х 210 mm

- 60-300 micron resolution

Anisoprint Composer allows you to enter the era of long fiber composites

- Endless fiber reinforced composites: 30 times stronger than pure plastic, 2 times stronger and lighter than aluminium

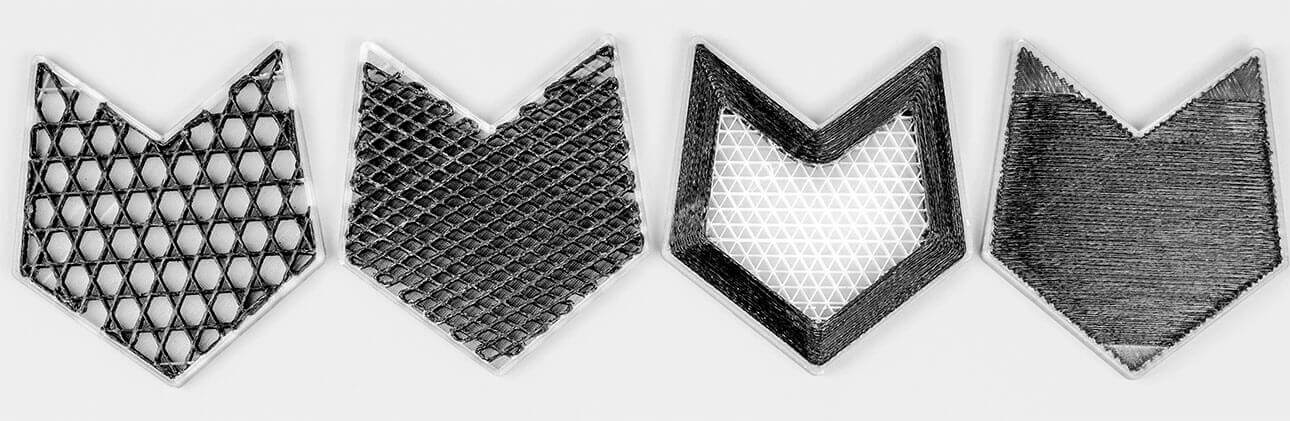

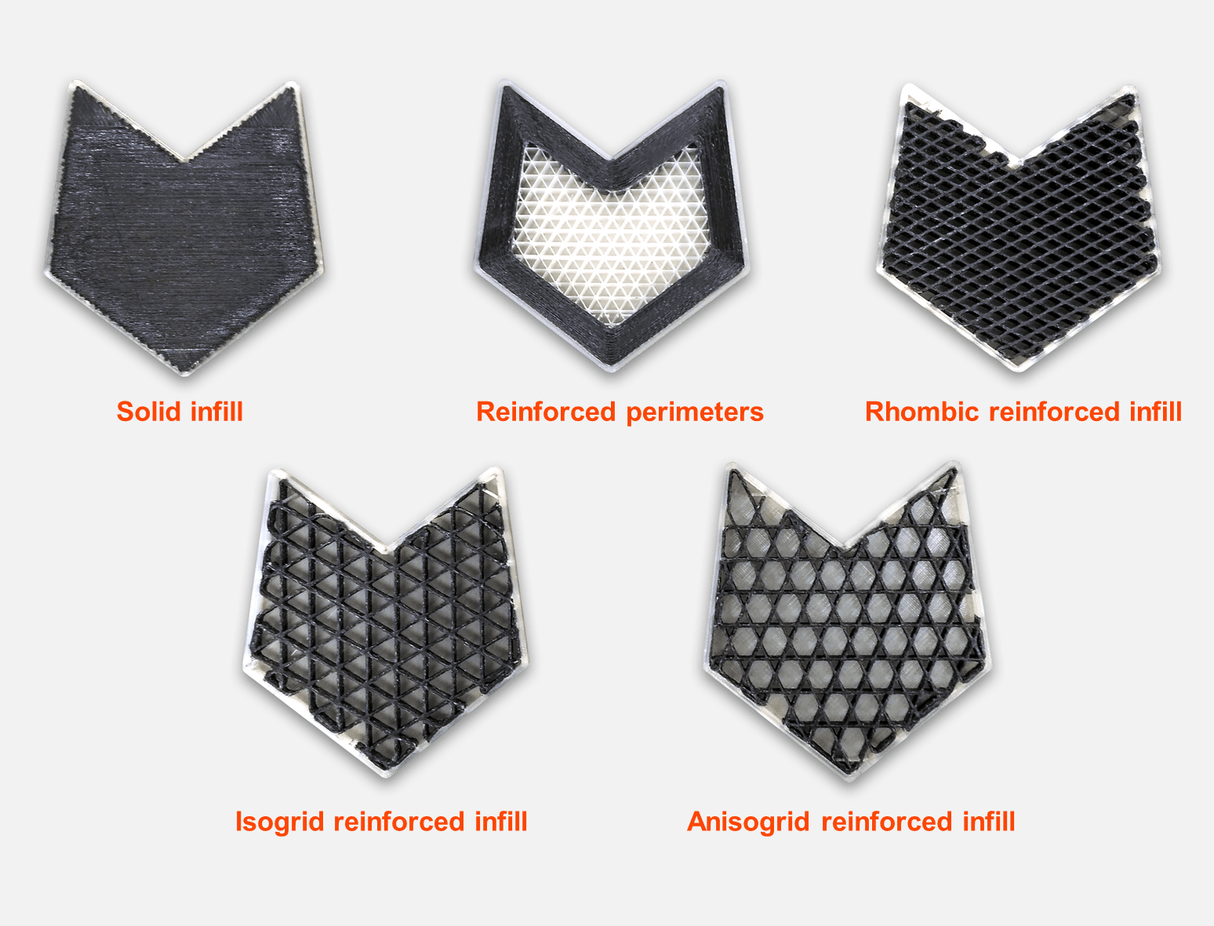

- optimal composite structures: lattice reinforcement - minimal weight, price and production time for the required strength

- A3 format: 420 mm х 297 mm х 210 mm construction volume

- open material system: use any plastic (up to a melting temperature of 270 °C)

- two reinforcement materials: CCF (carbon-based) and CBF (basalt-based)

- full control over fiber assembly generation with Aura slicing software

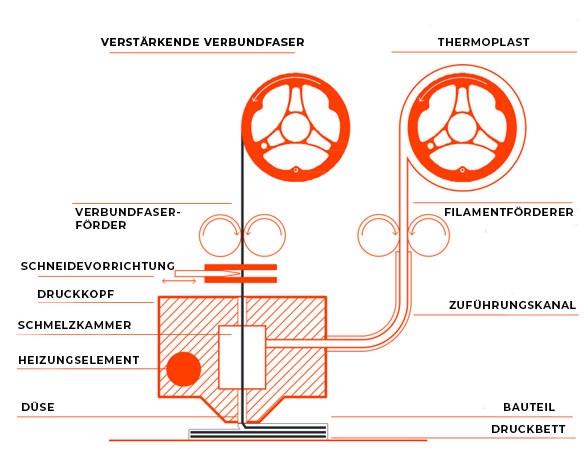

During printing

COMPOSITE FIBER COEXTRUSION

During printing, the thermoplastic is reinforced with composite fibers. The compound extruder has two inputs: one for reinforcement material and the other for the thermoplastic. Any plastic with a processing temperature of up to 270°C can be used as matrix material (e.g. PETG, ABS, PC, PLA, nylon, etc.).

The composite's strength and stiffness are along the grain, which is why the lattices, which are made up of one-dimensional ribs, represent the optimal shape for composites. With composite filling you get maximum strength with minimum use of materials, ie minimum weight, minimum production time and minimum price of the component.

What is anisoprinting?

Anisoprinting is a technology for producing optimal composite structures through 3D continuous fiber printing.

The solution is based on the patent-pending composite fiber coextrusion technology (CFC). Various thermoplastic polymers can be reinforced, consolidated and cured with continuous filaments in a one-step, fully automated process that requires no post-processing or tooling. The two-matrix approach (thermoset + thermoplastic) ensures low porosity, good adhesion of the fiber to the polymer and superior mechanical properties.

With the Anisoprint Composer A3 3D printer, you can print end-use parts that are stronger, lighter, and cheaper than their other material counterparts (metal, plastic, non-optimal composites).

Payment & Security

Payment methods

Your payment information is processed securely. We do not store any credit card information and do not have access to your credit card information.

Zertifizierte Sicherheit & Käuferschutz

Vertrauen Sie auf echte Bewertungen und zertifizierte Sicherheit beim Online-Kauf.

Price on request – your personal offer!

Use the " Price on request " function and get a

tailor-made offer for your desired product. We offer you the opportunity to request an individual price and thus make a unique bargain.

Contact us now for your individual offer!

![Polymaker PolyTerra PLA Dual 1,75mm 1kg - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/PolyTerra-Dual-PLA_1-75mm_1kg_Foggy-Purple-Purple_600x600_d536672b-71f5-4400-a9af-a045bd9a226d.jpg?v=1700312155&width=176)