Raise3D Pro3 3D printer with dual extruder

Raise3D Pro3 3D printer with dual extruder is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Raise3D Pro3 3D printer with dual extruder - the latest generation of the Raise3D Pro series.

Raise3D Pro3 3D printer with dual extruder - the latest generation of the Raise3D Pro series.

Take 3D printing to a new level with the new Raise3D Pro3 series for industrial-grade 3D printing quality.

The Pro3 series includes two dual-extruder 3D printers: the Pro3 with a build volume of 300 x 300 x 300 mm and the Pro3 Plus with a build volume of 300 x 300 x 605 mm. Evolved from the award-winning Pro2 series, the Pro3 series offers improved usability, higher effectiveness and industrial-grade repeatability, making it the best choice in this segment for any customer who 3D prints in agile production or in low-volume production used.

In terms of material compatibility, the Pro3 series is the printer with the widest potential in its segment, capable of printing any filament that extrudes up to 300°C, including PLA, ABS, HIPS, PC, TPU, TPE, NYLON, PETG , ASA, PP, PVA, glass fiber reinforced, carbon fiber reinforced, metal filling and wood filling, among others. Customers can expect superior results when using Raise3D filaments as well as third-party filaments approved under the Open Filament program.

The Pro3 series printers are easy to integrate into a production environment as they connect to Raise3D's 3D printing software ecosystem, which includes ideaMaker slicing software, ideaMaker open software template library and ideaMaker management software. Software RaiseCloud includes.

The most important new functions and improvements:

Interchangeable Hotends:

The Raise3D Pro3 Dual Extruder 3D Printer is equipped with an independent modular extruder with dual extrusion structure. This allows the Pro3 series to print with a wide variety of filaments while reducing clogging and allowing for convenient disassembly and component replacement, reducing machine downtime. The new interchangeable hotend system is ideal for users who frequently need to switch from non-abrasive to abrasive materials that require different nozzle types, or users who want to print at higher speeds and need different nozzle sizes. They feature a click-and-lock mechanism that requires no tools, and each is uniquely identified to track and record nozzle usage time.

Automatic bed leveling:

While the Pro2 series comes factory calibrated, requiring minimal or no calibration effort, the Pro3 series takes ease of use a step further and comes with automatic bed leveling. The new automatic bed leveling feature is a relevant tool for those who use printers for production purposes and want to implement a preventive maintenance program to ensure consistent quality of the final printed parts. Automatic bed leveling minimizes calibration time and increases productivity.

Air Flow Manager

The Pro3 Series Air Flow Manager is located on the back of the printer, improves heat dissipation and airflow, and creates a stable environment in the printing chamber. Equipped with a HEPA air filter, the Air Flow Manager can also filter and clean the air in the chamber. As long as it works within the recommended temperature range, the Air Flow Manager ensures the stability of the temperature in the chamber, which leads to better reproducibility of high-quality results regardless of the external conditions.

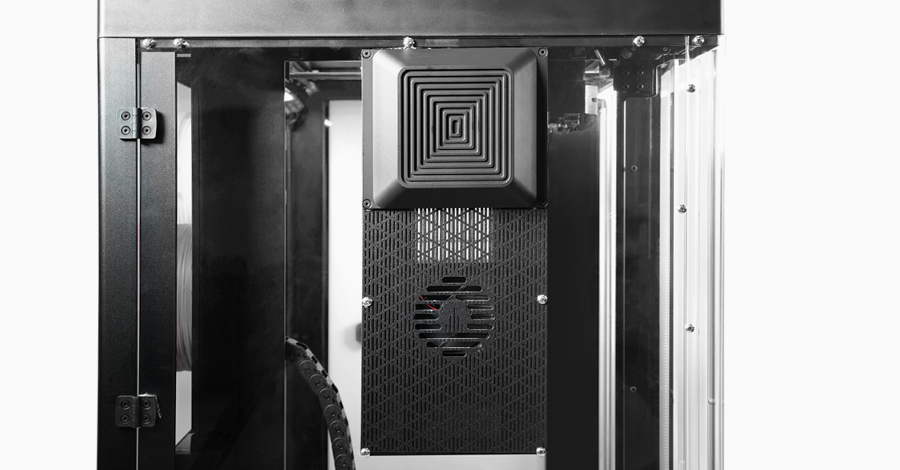

EVE Smart Assistant

The Raise3D Pro3 dual extruder 3D printer has a built-in intelligent assistant system called EVE. Similar to what is common with 2D printing, the EVE Assistant can guide users to pinpoint and fix issues that could affect the final print job. It also has a feature that analyzes printer usage and reminds users of planned interventions to ensure printer maintenance is done in a timely manner.

Raise3D is the first company in its segment to introduce such a feature, taking the usability of professional 3D printers to the next level.

More improvements

Among the other improvements, we highlight the following:

- Flexible build plate that allows for effortless removal of 3D printed parts

- Z-axis rod stiffness increased by 75% for more stable performance

- Automatic detection so when a door is opened, the door will pause immediately, print and resume after the door is closed

- Second-generation power recovery to save the printing status in the event of a power failure and resume printing from the same place after power is restored.

- Lightweight cable with digital temperature measurement

- HD camera with improved image quality and exposure sensitivity

- 1x power cord

- 1x USB storage device

- 1x ideaMaker software (download)

- 2x 1kg Raise3D Premium PLA Filament

- 2x metal rods for cleaning the hot ends

- 1x tweezers

- 1x set of Allen keys

- 2x filament spool holder

- 1x spatula

- 1x spare parts

- 2x Bowden tubes (guide tubes)

- 1x Heat Resistant Gloves

- 1x calibration card (metal)

Payment & Security

Payment methods

Your payment information is processed securely. We do not store any credit card information and do not have access to your credit card information.

Zertifizierte Sicherheit & Käuferschutz

Vertrauen Sie auf echte Bewertungen und zertifizierte Sicherheit beim Online-Kauf.

Price on request – your personal offer!

Use the " Price on request " function and get a

tailor-made offer for your desired product. We offer you the opportunity to request an individual price and thus make a unique bargain.

Contact us now for your individual offer!

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D_3D-Printer_Pro3.jpg?v=1760088767&width=1214)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Bildschirmfoto-2021-09-02-um-12-07-01_6164827c-7ef7-4b99-9975-fdbb3b1c0aaa.png?v=1760088767&width=1214)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/figure-4-Raise3D-Pro3-Series-Air-Flow-Manager4Cp3gfge9zB8r_bba9573b-b36c-4408-9544-0029e9de7ba9.jpg?v=1760088767&width=1214)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-Pro3-Series-Automatic-DetectionOoS6lRMPxkTqU_554133d4-2013-4a69-be8c-6f8ea912ca62.jpg?v=1760088767&width=1214)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-Pro3-Series-HD-Camera0IrVcXUJDvb6N_f5319971-1451-4066-89fa-a10281a0aff4.jpg?v=1760088767&width=1214)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-Pro3-Series-Flexible-Build-PlateraA36wbidaBMZ_14369a7d-6591-417a-b75e-141c968cd7bf.jpg?v=1760088767&width=1214)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-Pro3-Series-Lightweight-CableQPyMXB60xIwCF_1cdc463a-80d3-453d-b88e-ac23cb1afc6e.jpg?v=1760088767&width=1214)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/figure-5-Raise3D-Pro3-Series-EVE-Smart-AssistantixlPPksK5POLB_b2182f99-fb7a-4375-bfe1-1364765744a0.jpg?v=1760088767&width=1214)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/figure-3-Raise3D-Pro3-Series-Auto-Bed-Levelingz6d4sZoXgjW3C_520852c1-0e3b-4c14-9025-b840eab9892b.jpg?v=1760088767&width=1214)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D-Pro3-Series-Z-axis-Rod-Stiffness-IncreasedVhyec0Vh66aen_0e109afe-5c3a-43f3-9905-bb9082a1912d.jpg?v=1760088767&width=1214)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/figure-2-Raise3D-Pro3-Series-Hot-EndgroBlX9JzDZKt_d7449774-f8c3-4575-9090-cf25cc64f6e1.jpg?v=1760088767&width=1214)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D_3D-Printer_Pro3.jpg?v=1760088767&width=88)

![Polymaker PolyTerra PLA Dual 1,75mm 1kg - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/PolyTerra-Dual-PLA_1-75mm_1kg_Foggy-Purple-Purple_600x600_d536672b-71f5-4400-a9af-a045bd9a226d.jpg?v=1700312155&width=176)

![Raise3D Pro3 3D-Drucker mit Dual-Extruder - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/Raise3D_3D-Printer_Pro3.jpg?v=1760088767&width=640)