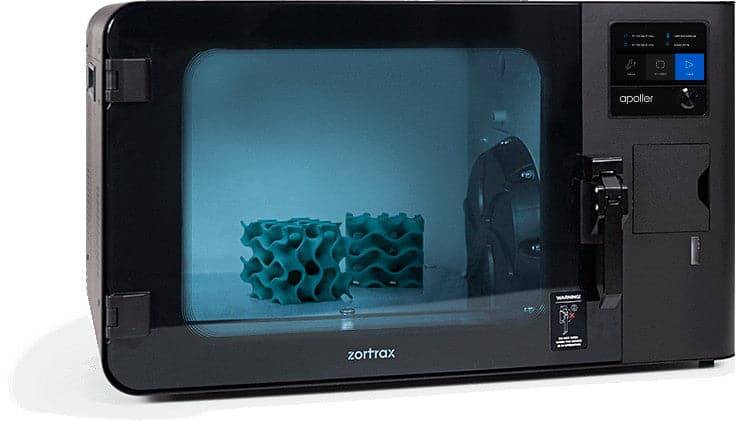

Zortrax Apoller - Intelligent steam smoothing device

Zortrax Apoller - Intelligent steam smoothing device is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Zortrax Apollo

Intelligent steam smoothing device for a variety of materials

Zortrax Apoller SVS (Smart Vapor Smoothing) is a revolutionary device that enables a new level of automation in the post-processing of FDM 3D printed models. The user simply opens the door, inserts the models and selects the appropriate settings via an intuitive touchscreen. The Apoller works with both acetone and MEK (ethanol) . It can smooth 3D models printed with Z-ABS, Z-ULTRAT, Z-ULTRAT Plus, Z-ASA Pro, Z-HIPS or similar third-party materials (e.g. PHA / PolySmooth).

Zortrax Apoller has advanced security systems with multiple levels of redundancy. For example, there are two sets of seals installed in the door to the Apoller's smoothing chamber. The device would work well with one set. The other is there just in case. This type of redundancy has been built into all of the Apoller's critical systems, designed in compliance with the ATEX directive 2014/34/EC setting safety standards for equipment used in potentially explosive atmospheres.

The main features of Zortrax Apoller are as follows:

- Smoothing chamber dimensions 300x250x250x250 mm

- Works in Zortrax SVS technology

- Works with MEK (Ethanol) and Acetone

- Has an intuitive touch interface

- Has Wi-Fi and Ethernet connectivity

- Smooths models printed with Z-ABS, Z-ULTRAT, Z-ULTRAT Plus, Z-ASA Pro and Z-HIPS.

- Works with external materials such as ABS, ASA and HIPS.

- Has an advanced vapor circulation system

- The maximum operating temperature is set at 90°C (194°F).

- The minimum operating temperature is down to -20°C (-4°F).

- The minimum absolute operating pressure is set to 0.4 bar.

- Safety systems meet the requirements of the EU ATEX directive.

speed and ease of use

The models must be placed in a double sealed smoothing chamber of 300x250x250x250 mm. Settings are then selected via an intuitive touchscreen. Once it's done, Zortrax Apoller only needs 3 hours to evenly smooth all models in the chamber.

SVS technology

The SVS technology in Zortrax Apoller is based on advanced proprietary algorithms that manage the temperature, pressure and concentration of solvent vapors in a double sealed, airtight smoothing chamber. The pressure in the chamber is kept below ambient at all times to prevent the fumes from escaping to the outside.

quality and efficiency

Vapors within the smoothing chamber are recirculated upwards to cover the model evenly. In this way, all surfaces are smoothed evenly. Once the smoothing process is complete, Zortrax Apoller lowers the temperature inside to condense the excess solvent and put it back into the tank. A 300ml bottle of acetone or MEK can be reused for multiple straightenings.

Certified security

Safety systems with several levels of redundancy have been developed to meet the high requirements of the ATEX Directive 2014/34/EC for the control of equipment for potentially explosive atmospheres. Because of this, Zortrax Apoller is easy to implement in workshops and safe to use.

Broad Compatibility

Zortrax Apoller works with both acetone and butanone (MEK), which are common and inexpensive solvents. The device can smooth 3D models printed with Z-ABS, Z-ULTRAT, Z-ULTRAT Plus, Z-ASA Pro and Z-HIPS or their third-party equivalents.

The appearance of injection molded parts

Zortrax Apoller can smooth 3D models printed with Z-ABS, Z-ULTRAT, Z-ULTRAT Plus, Z-ASA Pro and Z-HIPS or their third-party equivalents. HIPS-based materials can only be smoothed with MEK, while acetone is recommended for Z-ASA. For all other supported filaments, both acetone and MEK are applicable. Vapors' circulatory system ensures that even complicated models are evenly smoothed. Zortrax Apoller also dries the prints automatically and is therefore ready for use shortly after removing them from the smoothing chamber.

|

|

| A bike seat 3D printed with Z-ULTRAT smoothed with Zortrax Apoller to give a glossy finish. | A bike seat 3D printed with Z-ASA Pro, smoothed with Zortrax Apoller to get a matte finish. |

|

|

|

|

|

Step 1 Filling up the device

The solvent tank in the Zortrax Apoller needs to be filled with acetone or MEK, depending on the type of filament used to 3D print the models intended for smoothing. |

Step 2 Place models

The models must be placed 2-3 cm apart inside the smoothing chamber. The chamber must be closed to continue. |

Step 3 Select settings

The type of filament used to print the models and the type of solvent in the tank must be selected via an intuitive touchscreen. |

Step 4 Take out models

The models must be removed from the chamber after smoothing. They are dried out and safe to use straight away. No further steps are required. |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store any credit card information and do not have access to your credit card information.

Zertifizierte Sicherheit & Käuferschutz

Vertrauen Sie auf echte Bewertungen und zertifizierte Sicherheit beim Online-Kauf.

Price on request – your personal offer!

Use the " Price on request " function and get a

tailor-made offer for your desired product. We offer you the opportunity to request an individual price and thus make a unique bargain.

Contact us now for your individual offer!

![Polymaker PolyTerra PLA Dual 1,75mm 1kg - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/PolyTerra-Dual-PLA_1-75mm_1kg_Foggy-Purple-Purple_600x600_d536672b-71f5-4400-a9af-a045bd9a226d.jpg?v=1700312155&width=176)