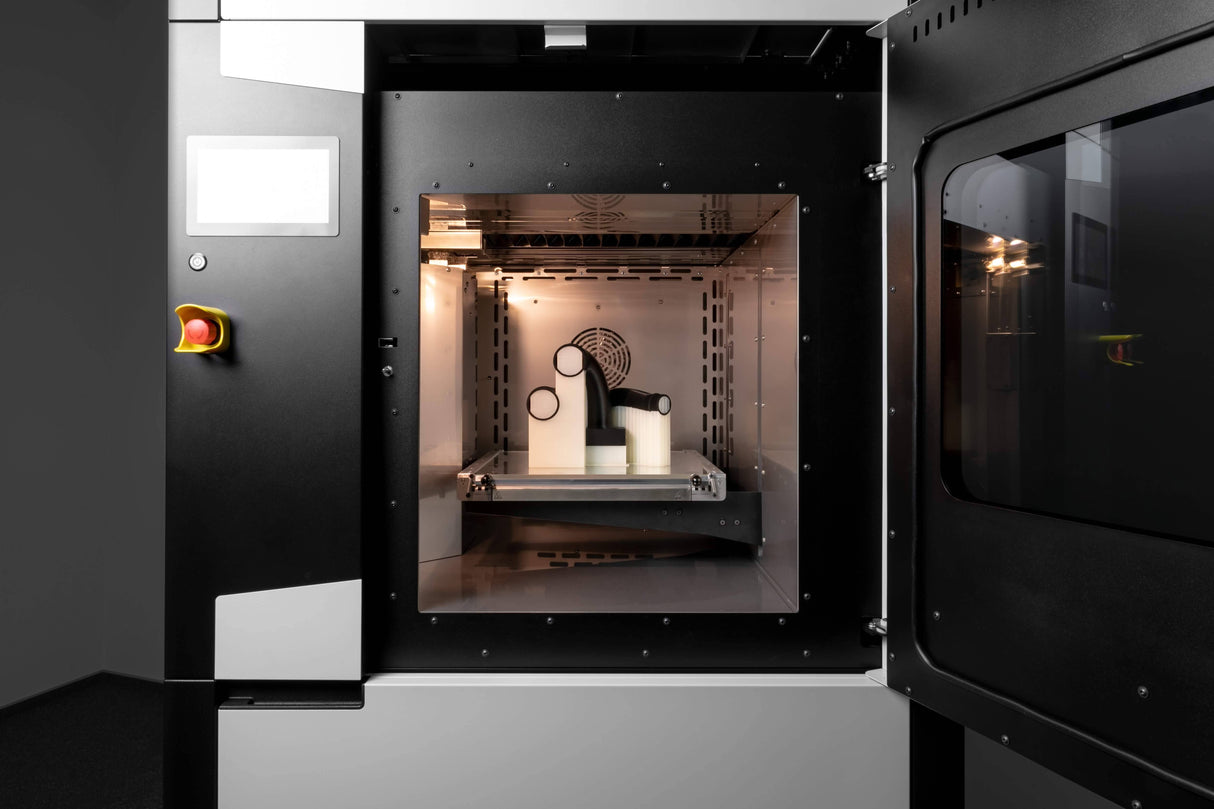

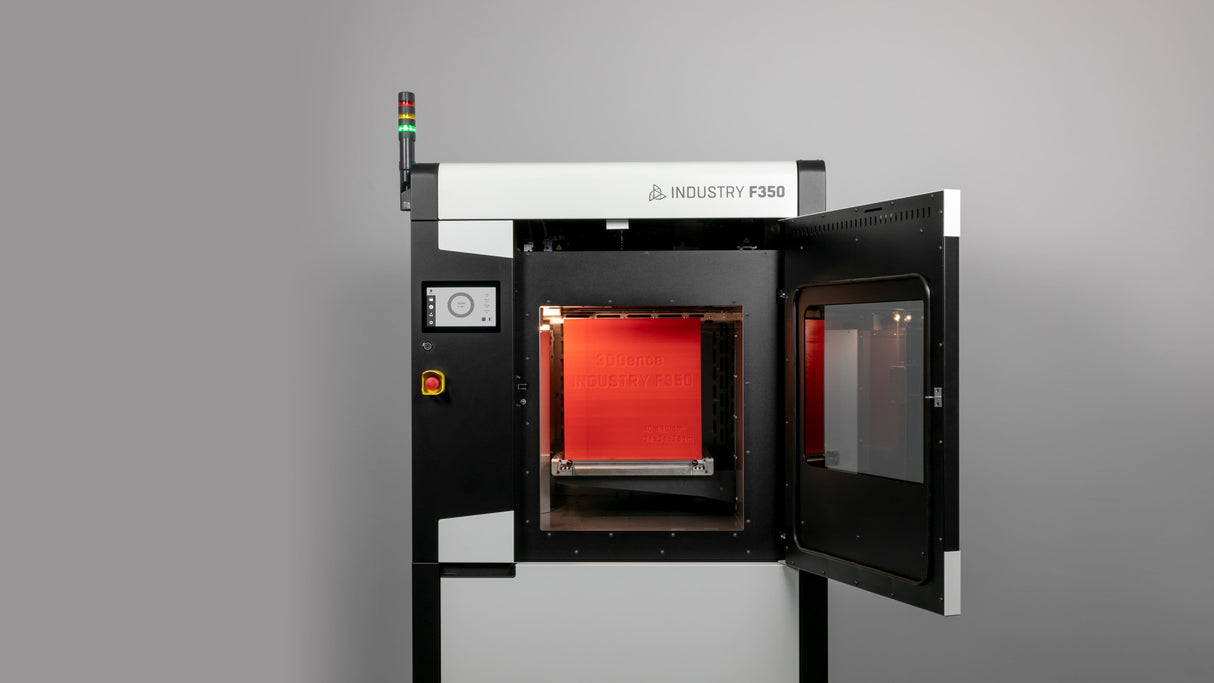

3DGence INDUSTRY F350 3D printer

High performance 3D printer - developed according to the Industry 4.0 concept

With the INDUSTRY F350, 3DGence closes the gap between the F340 and F421 3D printers. A powerful, versatile and innovative 3D printing system that conforms to the Industry 4.0 concept. The 3DGence INDUSTRY F350 delivers high-speed 3D printing and precise prototyping for fast and reliable results.

It's a prototyping workhorse that prints fully functional prototypes using a variety of materials. The 3D printer is optimized to get the best result in engineering materials and composites.

Key Features:

- Velocity - Accurate and rigid kinematic system

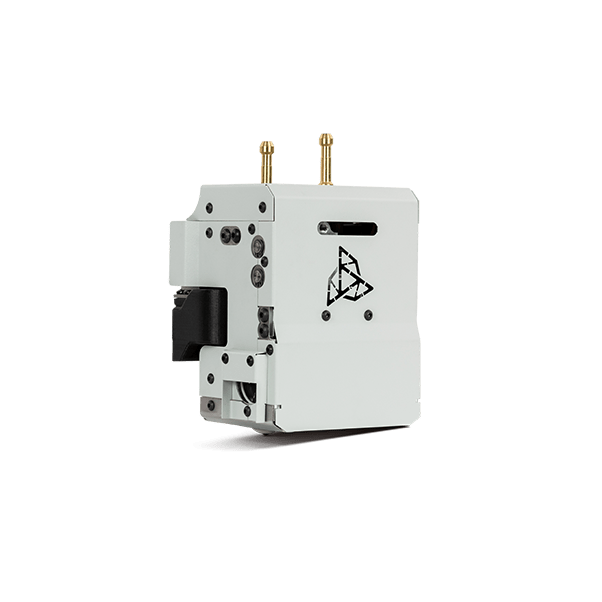

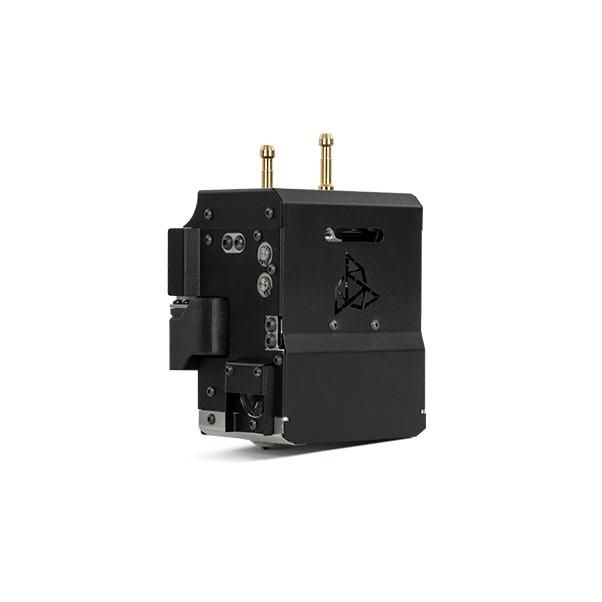

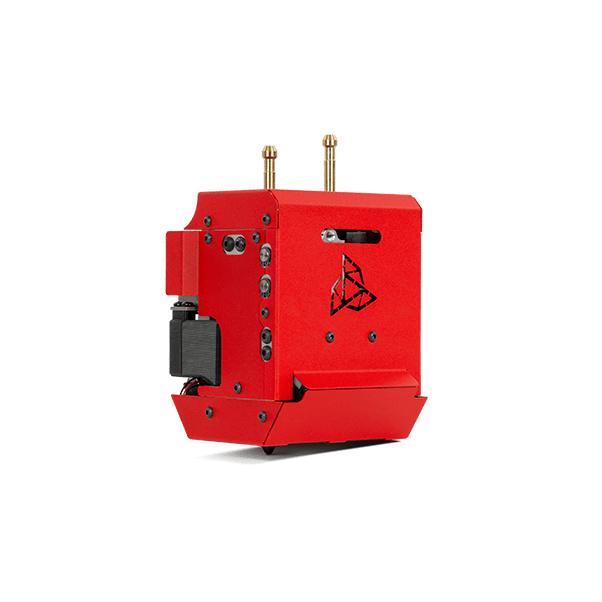

- Modular printing system - wide range of materials

- Ultra polymers (PEEK), technical grades (PC)

- Printing composites

- Soluble materials - carrier materials made of ESM 10, complex geometries

- 3DGence CLOUD - complete process control and monitoring

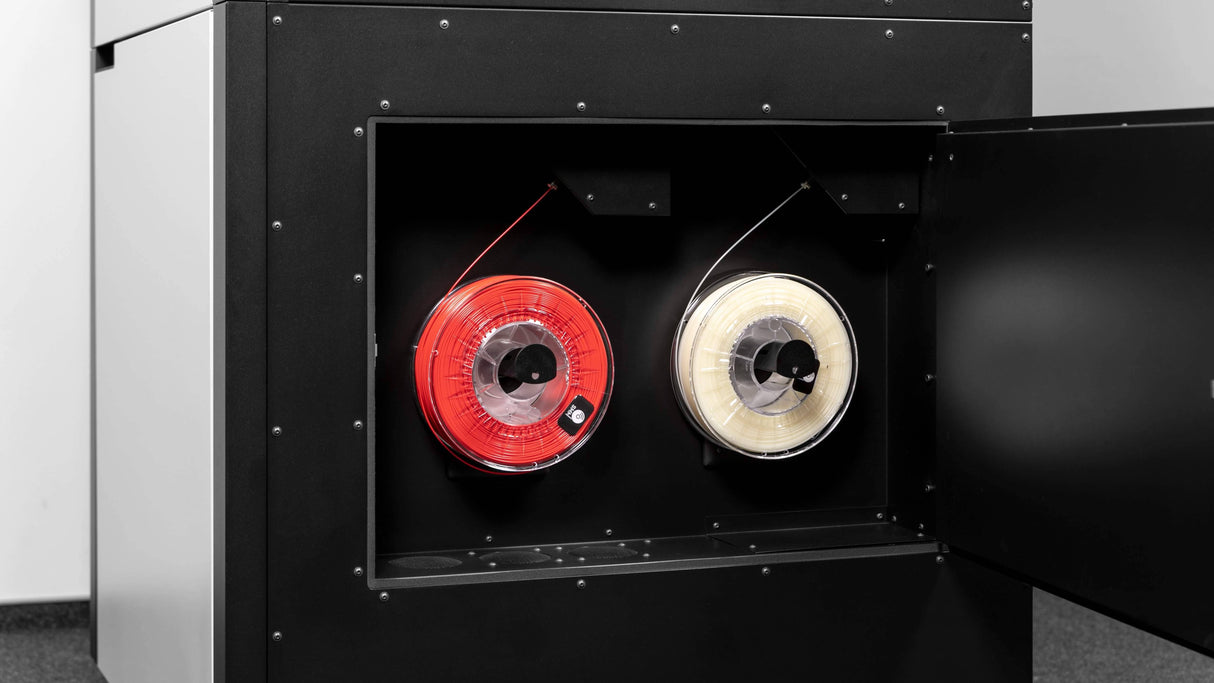

- Built-in SMM system for material detection

- Industrial Grade Accessories - Air Filter, Signal Tower and Backup Power Supply - SECURITY

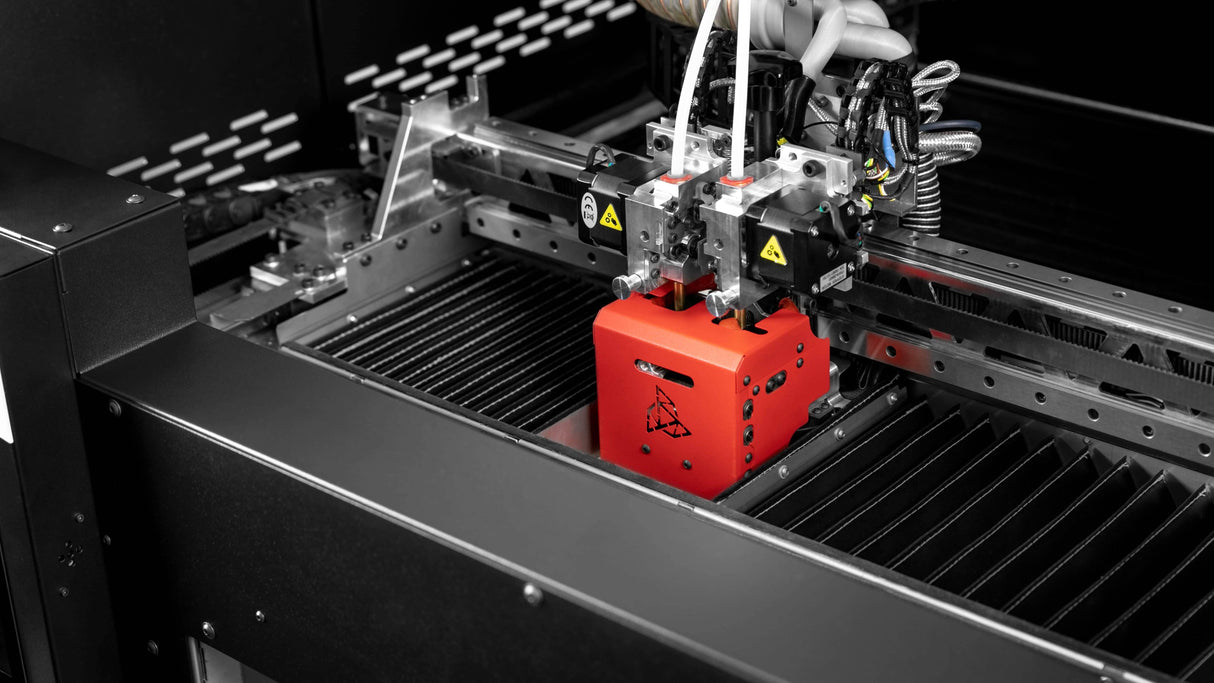

The 3DGence INDUSTRY F350 is a dual extruder 3D printer for industrial applications where accuracy, speed, convenience and safety of the entire 3D printing process are crucial. 3DGence INDUSTRY F350 is also suitable for working with a variety of engineered materials including high performance thermoplastics.

| SPECIFICATIONS _ | |

| Installation space (W × D × H) | 340×340×350mm |

| pressure nozzles | 2 per module |

| Hot end temp. (max) | 500°C |

| Build platform temp. (max) | 160°C |

| Installation space temp. (max) | 130°C |

| Filament chamber temp. (max) | 50°C |

| software |

3DGence SLICER 4.0 |

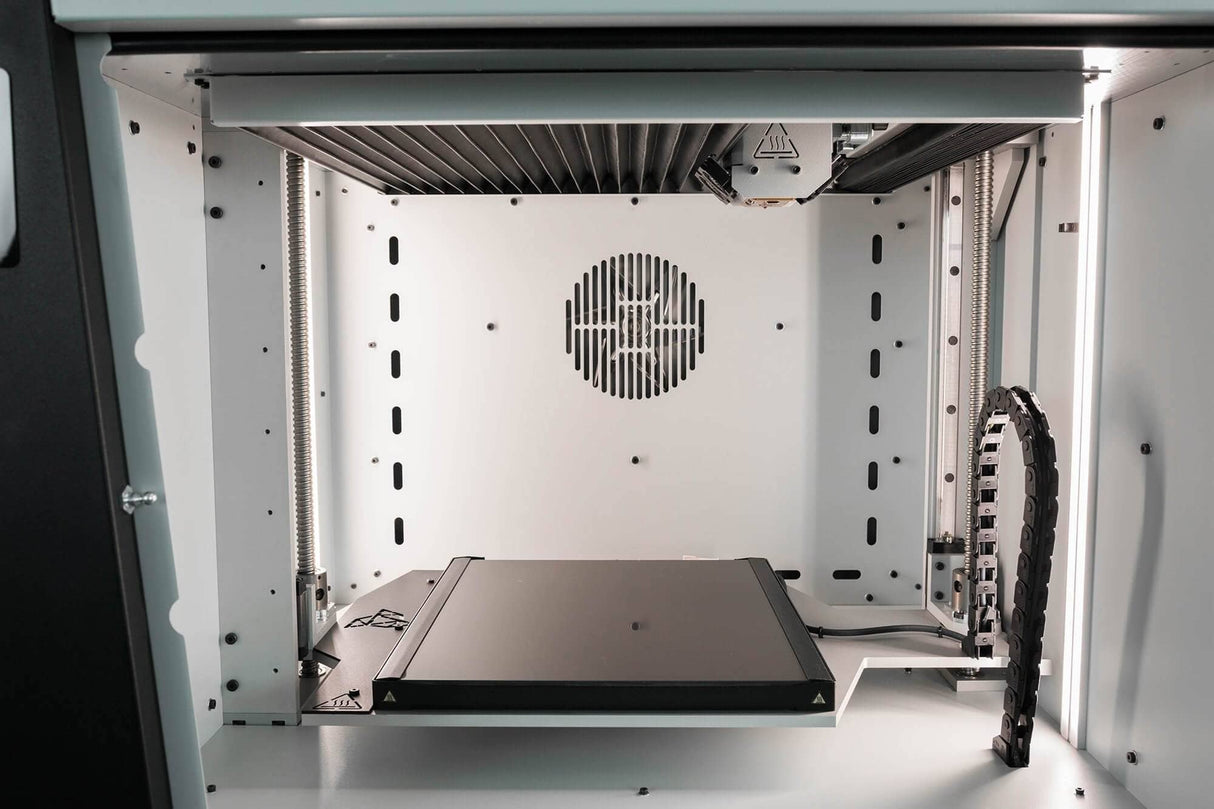

Large heatable space

F350 is equipped with an actively heated build chamber that can reach 130°C.

The combination of heated build space and heated material chamber ensures that the prints made from high-performance polymers such as PC or PEEK are always of the best possible quality. The build chamber, heated to 130°C, allows for the printing of PC blends or polycarbonate copolymers to ensure that the expected nominal mechanical properties are achieved without warping or other print failures. There is also a jet intake sector housed in the chamber.

Smart Materials Manager

- Z-section perforated mat as pre-filter in G4 standard

- H13 standard HEPA filter of filter efficiency of > 99.95%

- activated carbon cartridge

| Press: | Environmental conditions: | ||

| Printing technology: | FFF Fused Filament Fabrication | working temperature: | 18-30°C |

| build chamber: | 340×340×350mm | storage temperature: | -20 - 54°C |

| build volume: | 40,460cc | Energy requirement: | |

| min. layer height: | 50 µm | Power requirement: | - 230V 1ph 16A, CEE 7/7 plug - 2 x 120V 180° interfacial, NEMA 6I-20P 20A plug (USA) |

| Number of printheads: | 2, flushing system | Max. Input: | 3300W |

| nozzle diameter: | 0.5/0.5mm or 0.4/0.4mm | Average power consumption: | 1500W |

| Filament diameter: | 1.75mm | Communication: | Ethernet, Wi-Fi, USB drive |

| Printhead temperature: | 500°C | Software: | |

| Build Plate Temperature: | 160ºC | Slicing Software: | 3DGence SLICER 4.0 |

| Chamber Temperature: | 130 ° C (active heating) | Cloud-based services: | 3DGence CLOUD |

| Filament chamber temperature: | 50ºC | Security: | |

| Speed: | Filtering: | Advanced sensors of the filter unit | |

| travel speed: | 1000mm/s | Installation space lock, heat sensors, emergency switch | |

| Print speed: | up to 400mm/s | UPS device: | yes, optional |

| Construction: | Other: | Software Access Overdrive - Remote Shutdown | |

| Chassis: | steel | Dimensions & Weight: | |

| Outside: |

Steel, chamber lined with stainless steel |

External dimension: | 1825x960x940mm |

| build platform: | Borosilicate Glass / Magnetic Building Boards | Weight: | 335kg |

|

Positioning resolution XY: |

0.006mm | ||

| Positioning resolution Z: | 0.0007mm |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store any credit card information and do not have access to your credit card information.

Zertifizierte Sicherheit & Käuferschutz

Vertrauen Sie auf echte Bewertungen und zertifizierte Sicherheit beim Online-Kauf.

Price on request – your personal offer!

Use the " Price on request " function and get a

tailor-made offer for your desired product. We offer you the opportunity to request an individual price and thus make a unique bargain.

Contact us now for your individual offer!

![3DGENCE INDUSTRY F350 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/3dgence.png?v=1660773271&width=1214)

![3DGENCE INDUSTRY F350 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/F350_x2_thin.pngWhite.png?v=1660773280&width=1214)

![3DGENCE INDUSTRY F350 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/F350_3.pngWhite_69f4dcc0-aadc-47e4-81ca-af87742d41a3.png?v=1660773318&width=1214)

![3DGENCE INDUSTRY F350 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/F350_1.pngWhite_1.png?v=1660773357&width=1214)

![3DGENCE INDUSTRY F350 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/3dgence.png?v=1660773271&width=88)

![Polymaker PolyTerra PLA Dual 1,75mm 1kg - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/PolyTerra-Dual-PLA_1-75mm_1kg_Foggy-Purple-Purple_600x600_d536672b-71f5-4400-a9af-a045bd9a226d.jpg?v=1700312155&width=176)

![3DGENCE INDUSTRY F350 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/products/3dgence.png?v=1660773271&width=640)