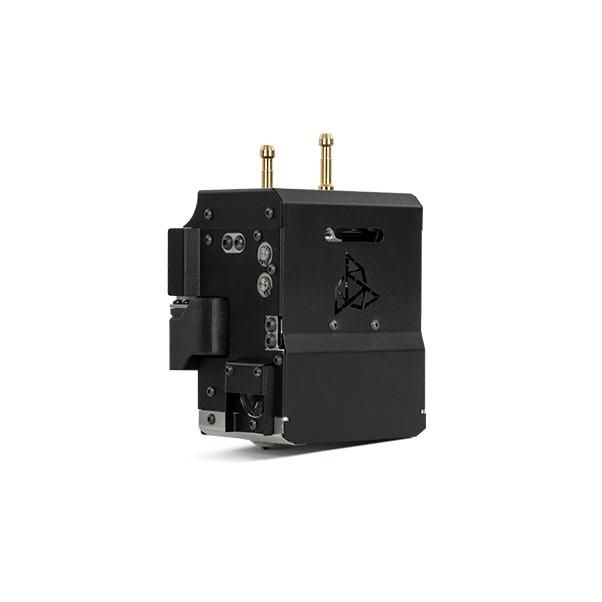

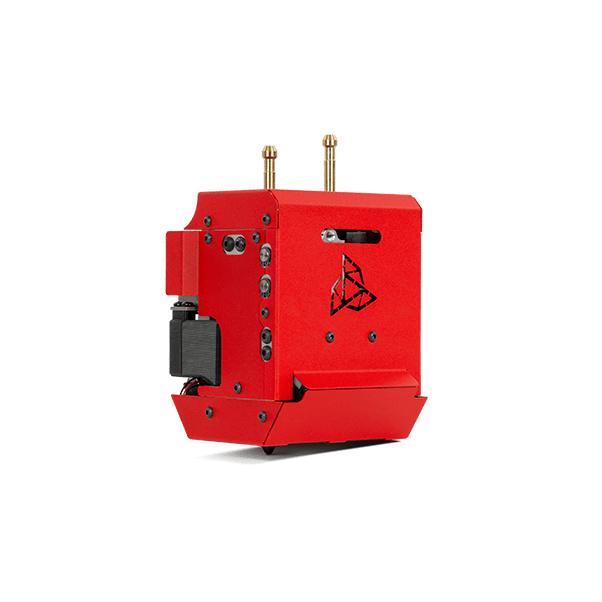

3DGence INDUSTRY F421 3D printer

Industrial high performance 3D printer - best in its class

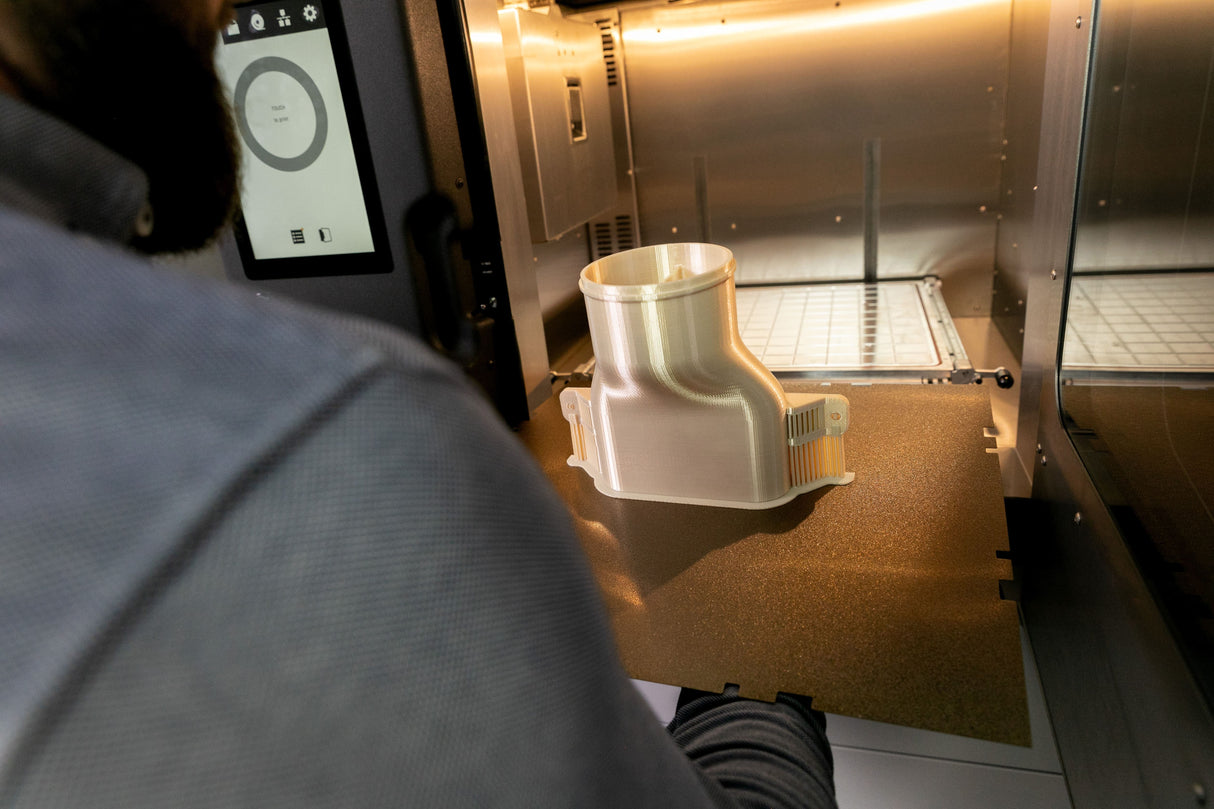

The new 3DGence INDUSTRY F421 is a high-speed 3D printer, developed according to the Industry 4.0 concept, that can print high-performance polymers such as ULTEM™, PEEK and PEKK - certified by TÜV Rheinland.

The highest quality, dimensional accuracy and repeatable results within your reach. This industrial 3D printer meets all expectations of a production system and impresses with its high-quality and solid workmanship. The new Industry F421 is considered to be the best in its class in terms of total cost of ownership, and a modular printing system also offers you the highest flexibility for your applications.

Powerful and fully-fledged manufacturing system for:

PRODUCTION

FAST | SECURE | RELIABLE | COST-EFFICIENT

Produce faster and more efficiently from materials used in industry

cheaper. Prepare spare or finished parts.

Durable and accurate production of final parts. Batch printing with large build volume. Cost reduction through high printing speed and short downtime.

PROTOTYPING

VERSATILE | PRECISE | SPACIOUS | CONNECTED

Accelerate your product development and shorten your path to market by replacing your traditional prototyping process with 3D printing. Using a 3D printer in the company can significantly reduce prototyping time.

Advantage over the competition with high-performance materials. Complex prototypes with soluble supports and large build volume. Controlled environment in a high-temperature chamber.

Main features:

PC, PC-ABS, PEKK-CF, ULTEM 9085, PEEK,

PEKK, VICTREX AM™ 200

Smart Material Manager

Large heated installation space

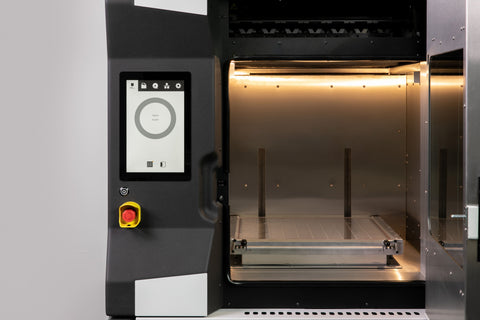

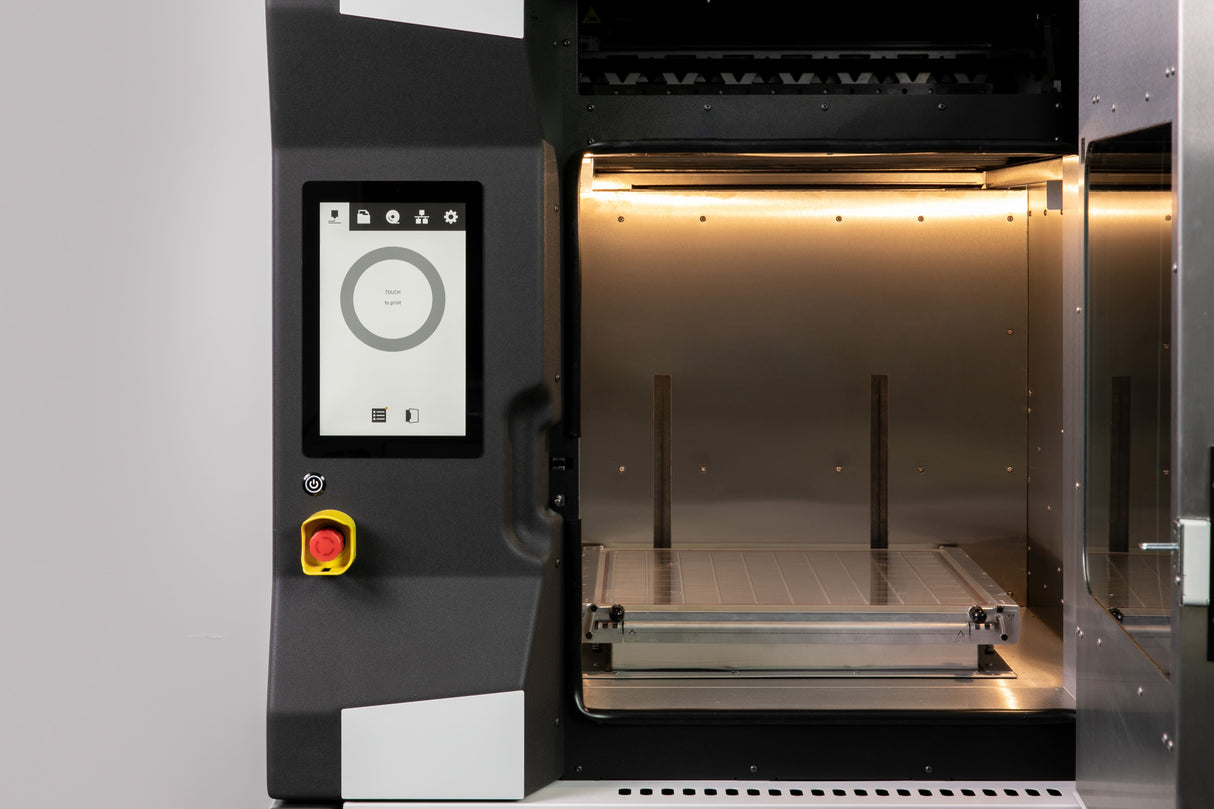

The 3DGence INDUSTRY F421 is equipped with a powerful actively heated build chamber that can reach 180 ° C. With a patent-pending variable chamber volume solution, the time required to reach working temperature remains minimal. The walls of the chamber are lined with INOX steel to prevent damage and oxidation.

The combination of heated build chamber, suitable extrusion temperatures and heated material chamber ensures that prints made from high-performance polymers such as PEEK or ULTEM™ filaments are always of the best possible quality and achieve the expected nominal mechanical properties without warping or other printing defects.

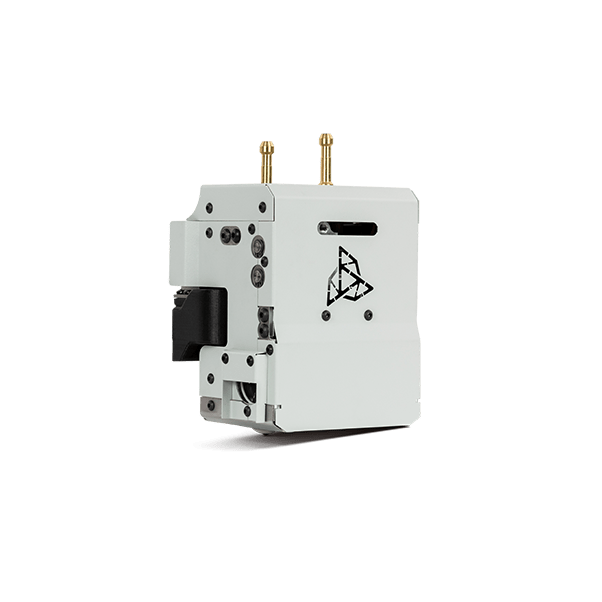

There is also a nozzle suction sector in the chamber. The F421 no longer relies on mechanical nozzle blocking, but instead uses printhead flushing. A flush cycle takes just 3 seconds.

Construction platforms

The F421 heated bed reaches 180 ° C and offers two options:

Borosilicate glass

Highly universal, mechanically resilient, easy, tool-free removal/replacement. Metal clamp sensor to detect the presence of building boards.

Plastic construction board

Specific use, very effective with certain material combinations.The user can switch between the usable build plates without additional tools or modifications to the machine. Vacuum functionality requires a compressed air connection at the printer installation location.

Automatic spool change

INDUSTRY F421 has four material bays that store four 1 kg material spools. By default, two are for model material and two for house material. When one spool runs out of material, the extruder automatically replaces it with the material from another bay.

The F421 can automatically change the spool during printing. Once the end of the filament is detected, the device loads material from the second slot without user intervention and continues printing seamlessly.

Heated material chamber

Material chutes are continuously heated to 50 ° C. This temperature can be set via the printer interface.

With specific coil geometry, it is possible to mount four 2 kg coils while retaining all functions.

Security

- An electronic lock on the main chamber door, which can also be controlled via cloud service and printer interfaces.

- Sensors for the main chamber door and the upper access hatch

- Redundancy for heat sensors of high-performance heating elements

- Emergency switch - instant power cut-off and heat control system

- System for emergency shutdown of logic

- Software access overdrive - the printer can be shut down remotely .

Filtration

With the focus on high performance thermoplastics, it is becoming increasingly important to provide adequate emissions control. F421 filters offer unparalleled filtration efficiency among FFF AM platforms .

F421 uses an advanced ULT filter unit that can filter the following particles:

- Macro dust

- Nanodust (VOC, UFP)

- solvent

- Steam (harmful gases)

- Foreign particles

UPS and Signal Tower

The F421 can be equipped with a 72 Ah UPS unit. The printer supports all functions during short power outages. The UPS is integrated into the system at a deeper level and monitors the UPS battery life. If the power outage is longer, the printer goes into idle support mode. Printing is paused and only the most important thermal control and logic functions remain. Should power be restored, printing will continue as normal. This dual approach can produce two results:

- Unaffected printer performance during short power outages

- longer battery life in case of prolonged power problems

Additionally, the 3DGence INDUSTRY F421 is equipped with a signal tower that indicates the status of the print. The signal tower makes the machine clearly visible from remote parts of the production facility.

3DGence Cloud

Remote print start, cancel and queue . Full control over job and execution, even on multiple printers.

Real-time monitoring of machine and printing status aggregation and presentation of machine and material consumption statistics access module;

The 3DGence support team can remotely access, diagnose, and provide assistance for file sharing and storage access control, as well as for managing marketing functions.

Live camera feed

Asymmetric encryption for data transmission (RSA)

New motherboard

F340 was based on a proprietary controller - the Titan. With Texas Instruments drivers, it was a superior motherboard at the time of its release. As performance requirements increased, a new controller had to be developed. The system is based on a 32-bit architecture and is highly adaptable and modular. It can support up to 9 stepper drivers, BLDC motors or servos.

The user interface and the entire user interface as well as the cloud services are run by a coprocessor. The main CPU focuses only on machine control. These two processing units run in parallel and do not affect each other's performance, saving enough processing power for instant job control.

Scope of delivery and additional options

WHAT'S INCLUDED?

- 3DGence INDUSTRY F421 3D printer

- Accessory kit (Wi-Fi module included)

- Signal tower

- Emergency stop button

WHAT IS THE ADDITIONAL EQUIPMENT?

- The M280 dual extruder printing module (+1 spool ABS, +1 spool ESM-10)

- The M360 dual extruder printing module (+1 spool PC, +1 spool ESM-10, +1 PEI heatbed)

- The M500 dual extruder printing module (+1 spool PEEK, +1 spool ESM-10)

- UPS - emergency power supply

- Advanced ULT LAS 42 filter unit

--

36 months warranty from the manufacturer for uninterrupted and fast production.

Technical data

| Press: | Environmental conditions: | ||

| Printing technology: | FFF fused filament fabrication | Working temperature: | 18-30°C |

| Construction chamber: | 380 × 380 × 420mm | Storage temperature: | -20-54°C |

| Construction volume: | 60,648 cm3 | Energy requirements: | |

| min. layer height: | 50 around | Required connection: | - 230V 1 hour with 32A (3n+p+e) IEC 60 309 plug (recommended) - 230V 1ph 20A direct connection |

| Number of print heads: | 2, Flushing system | Max. power consumption: | 4600W |

| Nozzle diameter: | 0.5 / 0.5mm or 0.4 / 0.4mm | Average power consumption: | 1500W |

| Filament diameter: | 1.75mm | Communication: | Ethernet, Wi-Fi, USB drive |

| Printhead temperature: | 500°C | Software: | |

| Building board temperature: | 180°C | Slicing software: | 3DGence SLICER 4.0 |

| Chamber temperature: | 180 °C (active heating) | Cloud-based services: | 3DGence CLOUD |

| Filament chamber temperature: | 50°C | Security: | |

| Achievable print part accuracy: | Parts are printed to an accuracy of 0.125 mm or 0.0014 mm/mm, whichever is greater. Z-axis accuracy includes an additional tolerance of 0.000/+ layer height. | ||

| Speed: | Filtering: | Advanced filter unit sensors | |

| Travel speed: | 1000mm/s | Sensors: | Installation space locking, heat sensors, emergency switch |

| Print speed: | up to 400mm/s | UPS emergency power supply: | Yes, optional |

| Construction: | Other: | Software Access Overdrive - Remote Shutdown | |

| Chassis: | Steel | Dimensions & Weight: | |

| Outside: | Steel, chamber lined with satin stainless steel | External dimensions: | 1900x940x900mm |

| Build platform: | Borosilicate glass / vacuum sealed plastic plates | Weight: | 365kg |

| Positioning resolution XY: | 0.006mm | ||

| Positioning resolution Z: | 0.0007mm |

| Press: | Environmental conditions: | ||

| Printing technology: | FFF Fused Filament Fabrication | working temperature: | 18-30°C |

| build chamber: | 380×380×420mm | storage temperature: | -20-54°C |

| build volume: | 60,648cc | Energy requirement: | |

| min. layer height: | 50 µm | Required connection: | - 230V 1 hour with 32A (3n+p+e) IEC 60 309 plug (recommended) - 230V 1ph 20A direct connection |

| Number of printheads: | 2, flushing system | Max. Input: | 4600W |

| nozzle diameter: | 0.5/0.5mm or 0.4/0.4mm | Average power consumption: | 1500W |

| Filament diameter: | 1.75mm | Communication: | Ethernet, Wi-Fi, USB drive |

| Printhead temperature: | 500ºC | Software: | |

| Build Plate Temperature: | 180℃ | Slicing Software: | 3DGence SLICER 4.0 |

| Chamber Temperature: | 180 °C (active heating) | Cloud-based services: | 3DGence CLOUD |

| Filament chamber temperature: | 50℃ | Security: | |

| Achievable printed part accuracy: | The parts are printed with an accuracy of 0.125 mm or 0.0014 mm/mm, whichever is greater. Z-axis accuracy includes an additional tolerance of 0.000/+ layer height. | ||

| Speed: | Filtering: | Advanced sensors of the filter unit | |

| traversing speed: | 1000mm/s | Sensors: | Installation space locking, heat sensors, emergency switches |

| Print speed: | up to 400mm/s | UPS backup power supply: | yes, optional |

| Construction: | Other: | Software access overdrive - remote shutdown | |

| Chassis: | steel | Dimensions & Weight: | |

| Outside: | Steel, chamber lined with satin stainless steel | External dimension: | 1900x940x900mm |

| build platform: | Borosilicate glass / vacuum sealed plastic panels | Weight: | 365kg |

| Positioning resolution XY: | 0.006mm | ||

| Positioning resolution Z: | 0.0007mm |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store any credit card information and do not have access to your credit card information.

Zertifizierte Sicherheit & Käuferschutz

Vertrauen Sie auf echte Bewertungen und zertifizierte Sicherheit beim Online-Kauf.

Price on request – your personal offer!

Use the " Price on request " function and get a

tailor-made offer for your desired product. We offer you the opportunity to request an individual price and thus make a unique bargain.

Contact us now for your individual offer!

![3DGence INDUSTRY F421 - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/AJ4A3453.png?v=1660772834&width=1214)

![3DGence INDUSTRY F421 - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/AJ4A3455.png?v=1660772888&width=1214)

![3DGence INDUSTRY F421 - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/AJ4A3456.png?v=1660772942&width=1214)

![3DGence INDUSTRY F421 - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/AJ4A3425.jpg?v=1660773017&width=1214)

![3DGence INDUSTRY F421 - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/AJ4A3453.png?v=1660772834&width=88)

![Polymaker PolyTerra PLA Dual 1,75mm 1kg - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/PolyTerra-Dual-PLA_1-75mm_1kg_Foggy-Purple-Purple_600x600_d536672b-71f5-4400-a9af-a045bd9a226d.jpg?v=1700312155&width=176)

![3DGence INDUSTRY F421 - [3dmaterial-shop]](http://3dmaterial-shop.de/cdn/shop/products/AJ4A3453.png?v=1660772834&width=640)