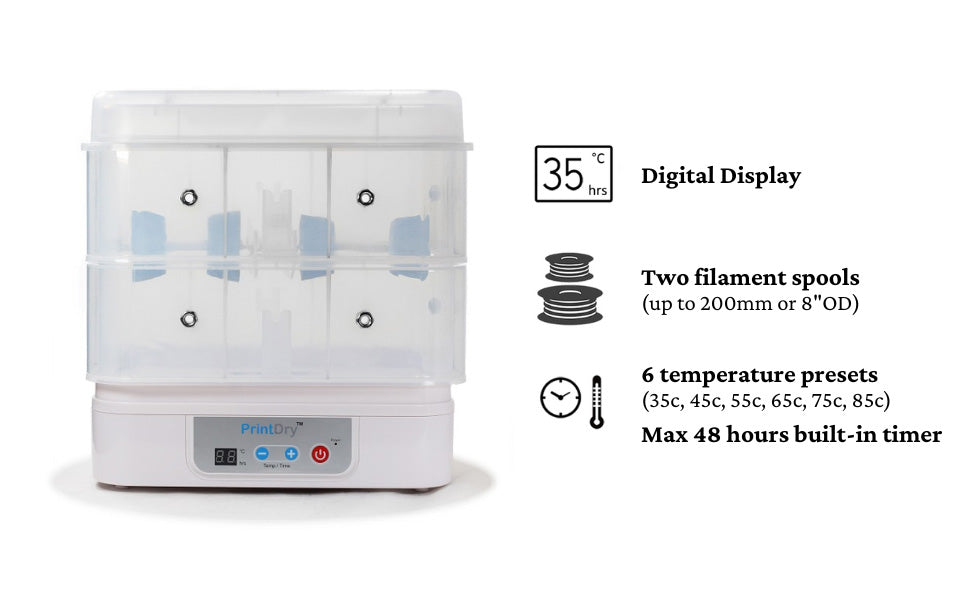

PrintDry Filament Dryer PRO3

Professional material drying for high-quality 3D printing

- Easily adjust the temperature with 6 presets (35 °C, 45 °C, 55 °C, 65 °C, 75 °C and 85 °C).

- Built-in timer with a maximum time of 48 hours.

Note : The temperature readings are measured directly at the tip of the temperature sensor, which is located about 15mm from the hot air outlet. The temperature distribution inside the dryer is NOT uniform. The temperature is higher in a location near the hot air outlet, and lower in a location far from the hot air outlet.

Features:

- Digital Display

- Automatic switch-off: A timer of max. 48 hours switches off automatically after drying.

- Temperatures: 35°C - 85°C, adjustable for different filament types

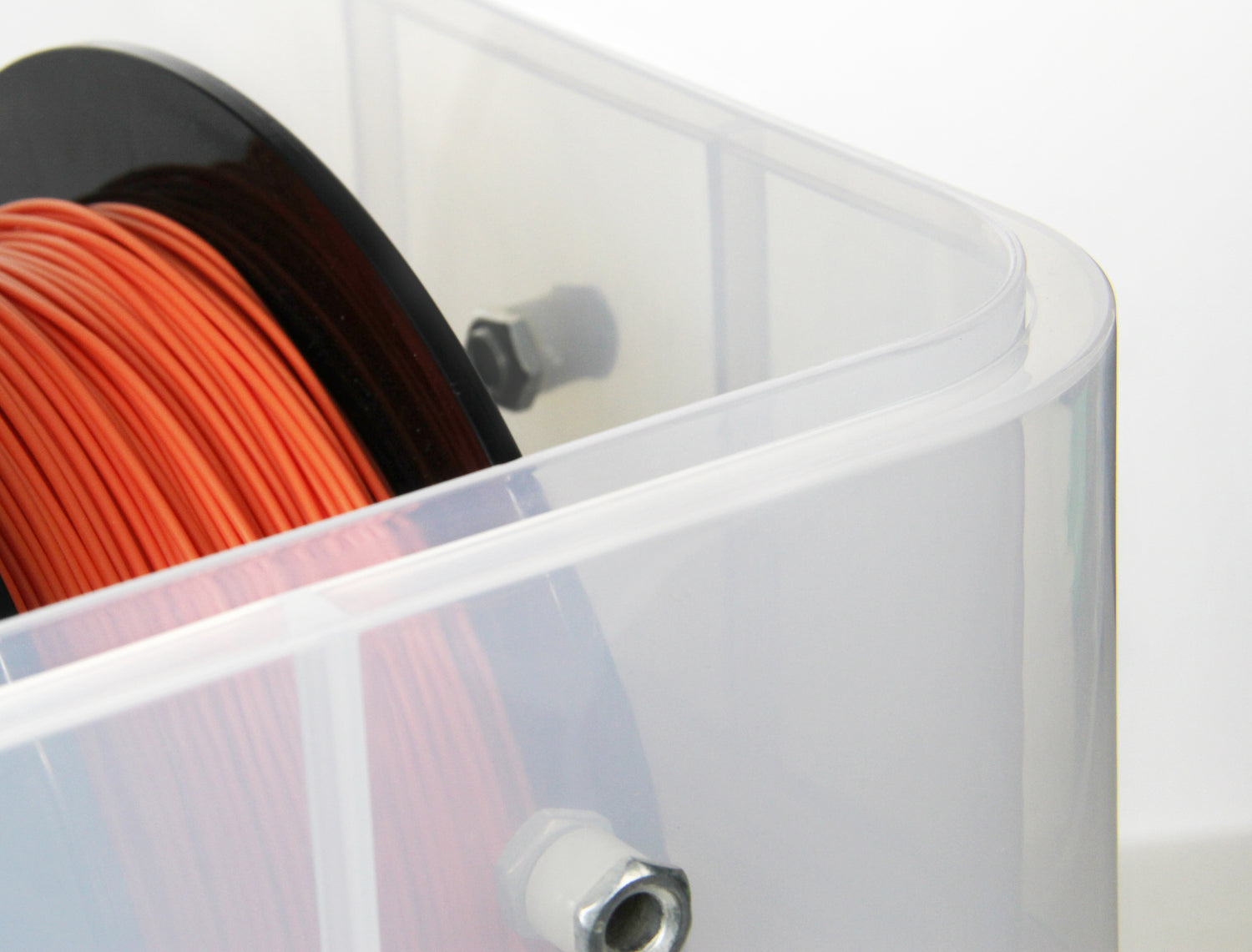

- Filament spools: Two commercially available filament spools with a maximum diameter of 20cm can be dried in parallel

- CE/TÜV and ETL certified

- The filament outlets on the front allow 1.75mm and 2.85mm filaments to be fed to the 3D printer directly from the dry box.

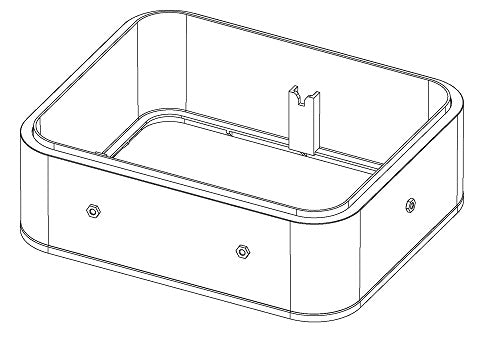

- Expandable to fit one large spool or 4 small spools

- Recommendation: Equip the box inside with silicate bags (protection against moisture absorption)

The temperature values are measured directly at the tip of the temperature sensor, which is located approximately 15 mm from the hot air outlet, under the following conditions.

- The ambient temperature is 22 °C.

- There are two full filament spools in the dryer.

- The dryer has been running at the set temperature for at least 1 hour

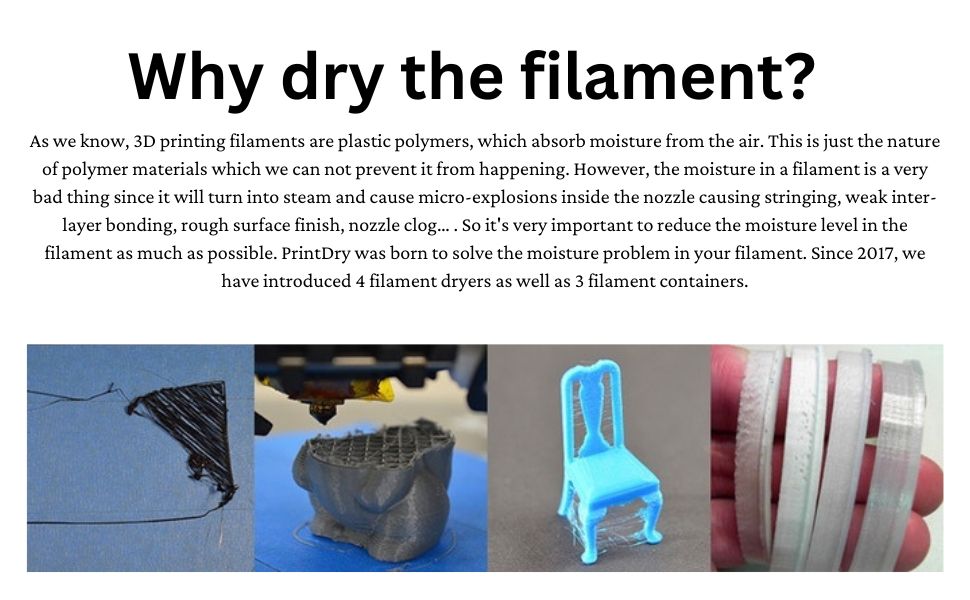

Reasons and advantages for drying filaments.

Filament drying, especially in 3D printing applications, is extremely important for a variety of reasons and offers a variety of benefits. Here are some reasons why filament drying plays a crucial role:

1. ** Humidity control **: Filaments, especially those made of materials such as PLA, ABS, Nylon and PETG, can absorb moisture from the environment. This moisture absorption can lead to quality problems such as blistering and bumps in the printed object. Filament drying helps to reduce moisture and thus improve print quality.

2. ** Improved print quality **: Moisture in the filament can cause vapor to form during the printing process. This can lead to unwanted bubbles and surface defects in the printed object. Drying the filament minimizes this problem, resulting in better print quality overall.

3. ** Avoid nozzle clogging **: Moisture can build up in the print head and cause clogging in the print nozzle. This can interrupt the printing process and even damage the nozzle. Dry filament greatly reduces the risk of nozzle clogging.

4. ** Consistent material properties **: Filaments are often selected with specific material properties, such as mechanical strength, flexibility or heat resistance. Humidity can change these properties and lead to unexpected results. By drying the filament, the material properties remain consistent and predictable.

5. ** Fewer print aborts **: Dry filament reduces the likelihood of print aborts and misprints. This not only saves time, but also material and resources.

6. ** Extended shelf life **: Dry filament can be stored for longer without affecting its quality. This is especially important if filament rolls are not used immediately after purchase.

7. ** Less post-processing **: Objects printed from dry filament require less post-processing as they have fewer anomalies and defects, saving time and effort after printing.

8. ** Economic Efficiency **: Using dried filament increases the overall efficiency of the printing process. Less scrap and better print results mean less material is wasted, ultimately leading to cost savings.

9. ** Wider range of materials **: Due to their delicate nature, some materials require careful drying before they can be printed. The ability to print different materials with different requirements opens up a wider range of application possibilities.

In summary, filament drying has a significant impact on print quality, reliability of the printing process and economics. It is an essential step to get the best results from 3D printing while maintaining the lifetime and quality of the filament used.

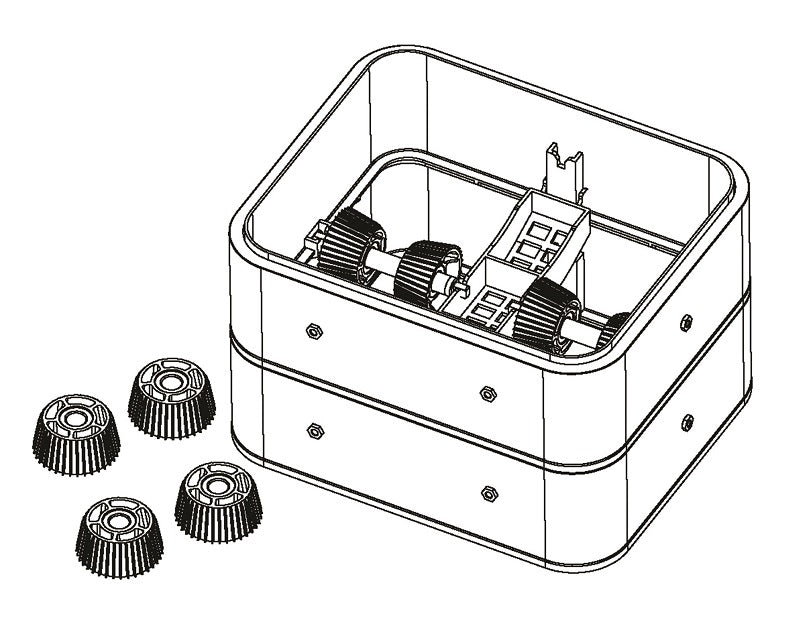

- 2 metal shafts

- 4 large coil adapters

- 4 small coil adapters

Payment & Security

Payment methods

Your payment information is processed securely. We do not store any credit card information and do not have access to your credit card information.

Zertifizierte Sicherheit & Käuferschutz

Vertrauen Sie auf echte Bewertungen und zertifizierte Sicherheit beim Online-Kauf.

Price on request – your personal offer!

Use the " Price on request " function and get a

tailor-made offer for your desired product. We offer you the opportunity to request an individual price and thus make a unique bargain.

Contact us now for your individual offer!

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/600821440005.jpg?v=1694032450&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/2.jpg?v=1694032450&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/features3.jpg?v=1694032450&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/CopyofPrintDry_dryer_2.jpg?v=1692962624&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/CopyofdryerPRO.jpg?v=1692962624&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/CopyofPrintDry_dryer_2s.jpg?v=1692962624&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/CopyofPrintDry_dryer_2ws.jpg?v=1692962624&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/CopyofPrintDry_dryer_2sws.jpg?v=1692962624&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/LSK2003-PROss.jpg?v=1692962624&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/ACKdryer2.0.jpg?v=1692962624&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/CopyofIMG_6845.jpg?v=1692962624&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/ACK2003-PROss.jpg?v=1692962624&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/CopyofLSK_PRO_double-wall.jpg?v=1692962624&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/CopyofACK2003.jpg?v=1692962624&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/1_85211add-a3f7-4ece-9e49-e26535e80ba5.jpg?v=1692962345&width=1214)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/600821440005.jpg?v=1694032450&width=112)

![Polymaker PolyTerra PLA Dual 1,75mm 1kg - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/PolyTerra-Dual-PLA_1-75mm_1kg_Foggy-Purple-Purple_600x600_d536672b-71f5-4400-a9af-a045bd9a226d.jpg?v=1700312155&width=176)

![PrintDry Filament Dryer PRO3 - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/600821440005.jpg?v=1694032450&width=640)