- Low stock - 5 items left

- Inventory on the way

Materials Management System (MMS)

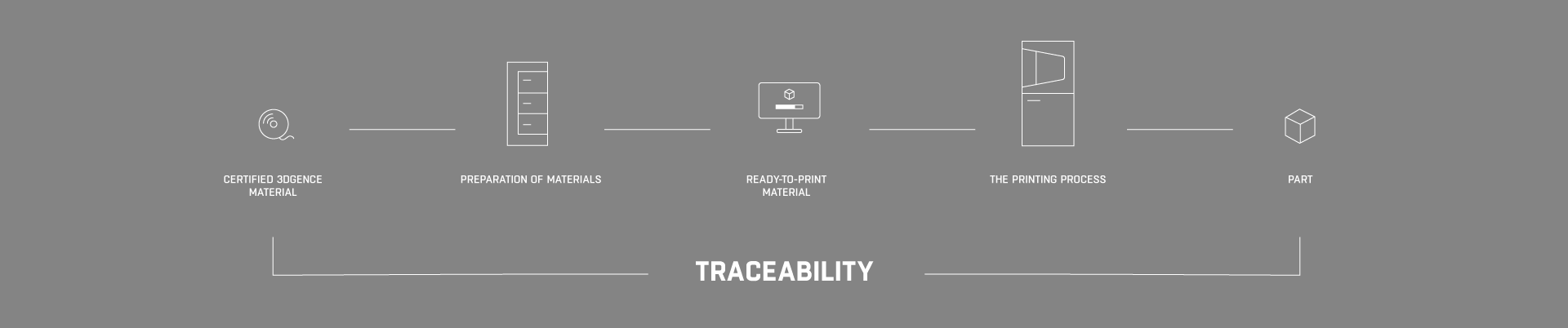

Reproducibility, precision and full traceability of the printing process.

3DGence MMS automates material storage, preparation and post-print annealing – making successful printing of ultra-polymers such as PEEK, ULTEM™ and composites accurate and simplified.

As the transition from prototyping to end-use parts has become a reality through industrial-grade 3D printers and advanced materials, automation and pre-configuration ensure print success.

Improper handling and preparation of materials can lead to moisture ingress, printing defects, warping and poor visual quality - resulting in inaccurate parts and significantly reduced productivity.

Ensure print productivity, part integrity and the highest quality with our materials management system.

functions

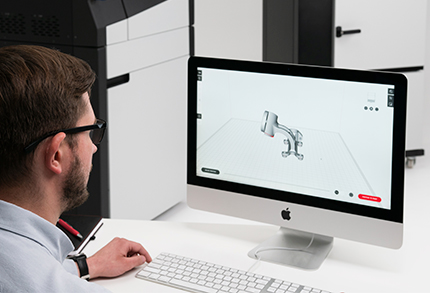

Process control and traceability of part impressions

Record the materials contained in the certified material database in your process and achieve full traceability of your materials. Each spool of material purchased from 3DGence is equipped with the NFC tag with a unique ID. Once opened, the material is recorded in the MMS system and the information can be sent to the 3DGence CLOUD and tracked until the end of the production process performed on the MMS or 3DGence INDUSTRY line printer, which is monitored and recorded in process diaries.

Drying and preparation of the material

Minimize the risk of failure or production downtime by using an appropriate material that is handled with care and according to the manufacturer's requirements. Select a certified 3DGence material using the material management system, with the MMS system showing you how to handle that material, then the drying and storage program is started automatically. Each material is dried and stored according to the requirements specified for that class of material. The system selects and indicates the exact location for drying and storing a coil.

annealing of the parts

Perform heat treatment on end elements printed from PAEK. With the MQL system you can achieve high-performance parts printed from PAEK that are even more durable. Use the parts annealing program implemented in the MQL system. The specially developed PAEK annealing process was used to achieve the highest quality, semi-crystalline ultra-polymer parts. PEEK and Victrex AM200 FL from the 3DGence Certified Materials Database.

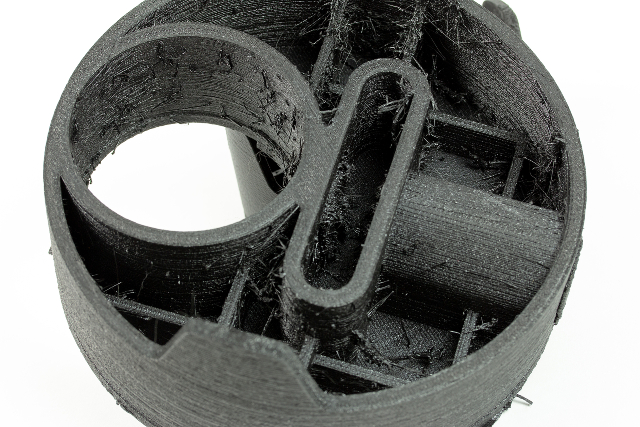

Without material processing

Material preparation automated with MQL

Parts printed from improperly stored materials have poorer mechanical properties and optical quality.

The pre-programmed MQL preparation modes ensure durable and accurate prints without visual errors.

3DGENCE CONNECT

3DGence MMS benefits from 3DGENCE CONNECT, a constantly expanding and fully connected system between software, hardware and process control - with more connected functions coming soon. Rely on control and traceability throughout the printing process, from design to part.

Scan the material into the MMS to register it in your printing process and get full material traceability. Proper material management is critical to part quality and integrity. We make it easy and make sure it stays connected. Our application engineers are ready to explain the technical details of the 3DGence Connected System.

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/3dgence-material-managment-system_MMS.jpg?v=1685393997&width=1080)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/mms-Krzysztof-podmiana.jpg?v=1685393997&width=1080)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/kolaz_3-scaled.jpg?v=1685393997&width=1080)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/2-1024x480.jpg?v=1685393997&width=1080)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/MMS-JPG-3.jpg?v=1685393997&width=1080)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/4_430_293.jpg?v=1685393997&width=1080)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/image_f8685f55-ff85-457e-83b0-38059db5b351.png?v=1685393997&width=1080)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/3dgence-material-managment-system_MMS.jpg?v=1685393997&width=720)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/mms-Krzysztof-podmiana.jpg?v=1685393997&width=720)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/kolaz_3-scaled.jpg?v=1685393997&width=720)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/2-1024x480.jpg?v=1685393997&width=720)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/MMS-JPG-3.jpg?v=1685393997&width=720)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/4_430_293.jpg?v=1685393997&width=720)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/image_f8685f55-ff85-457e-83b0-38059db5b351.png?v=1685393997&width=720)

![3DGence Material Management System (MMS) - [3D Material-Shop]](http://3dmaterial-shop.de/cdn/shop/files/mms-Krzysztof-podmiana.jpg?v=1685393997&width=1000)